Fiber Optic Taper (FOT)

Fiber Optic Taper (FOT)

Couldn't load pickup availability

Fiber optic taper is a device that can transfer an optical image from one end to another with a different size. It consists of a bundle of optical fibers that are arranged in a tapered shape, meaning that the diameter of the bundle changes along the length of the device. The taper ratio is the ratio of the input diameter to the output diameter, and it determines the magnification or demagnification of the image.

Fiber optic tapers can be used for various applications, such as adapting an image to a sensor with a different size, concentrating light energy, or reducing the size of optical systems.

- 1.5x – 6x Image Magnification (or Concentration)

- Compact Structure (Less bulky than Lens System)

- No Spherical, Coma aberration

- Easy Configuration (Directly coupling to Sensors)

Specification Explainer

-

(Large End) Fiber Diameter

The fiber size on large end of the taper

- Typical Value: 6.0um / 10.0um

- Min Value: 4.0um

- Max Value: 15.0um

*Note: The fiber diameter is different on big end and small end.

-

(Small End) Fiber Diameter

The fiber size on the small end of the taper.

*Note: This is a dependency value, which related to Magnification ratio and Large End Fiber Diameter

- Typical Value: 3.0-5.0um

- Min Value: 1.8-2um

- Max Value: NA

-

Magnification Ratio

Key Parameter of Fiber Optic Taper. Defines the Magnifying power of the component.

- Typical Value: 1.5x-3x

- High Value: 3.1x- 6.0x

*Note:

- Higher magnification ratio may reduce the light transmission further.

- FOT with 3X magnification usually needs customization.

-

Surface Size

The large end surface size that can be made.

- Typical Value: dia15-dia50mm

- Min Value: 7.5mm

- Max Value: 100mm

-

Shape

The geometric of Large end and Small end of the Fiber Optic Taper.

Typical Shapes:

- Round to Round

- Square to Square

Availablility: Square, Round, Step, Concave

-

Numerical Aperture (N.A)

The numerical aperture (NA) for fiber is a measure of the range of angles within which light that is incident on the fiber will be transmitted along it.

- Theorical Value: 1

- Practical Value: 0.65 - 0.85

*Note:The numerical aperture here is referred to N.A on small end.

-

Resolution

The resolution here is expressd in the terms of lp/mm.

Typical Value:

- 50lp/mm (10um)

- 102lp/mm (6um)

- 166lp/mm (3um)

- 230lp/mm(2um)

*Note:Testing with USAF1951, all results are under theoretical testing condition.

"lp/mm" is a pair of black and white squares in object space, which are the smallest elements that can be distinguished by the system.

-

Material Characteristic

- Thermal Expansion Coeff.

(20-300°)

= (60-90) x 10**(-7) / °C - Vacumm Tightness

< 10 - 12Pa · m3/s - Transmission (Collimated Light)

Approx 75 ~ 85% - Wavelength Range

400nm ~ 1400nm - Interestital Fibers (EMA)

Yes - XRAY Absorption

Yes

*Note:EMA are used to absorb the stray light inside the fiber optic taper.

- Thermal Expansion Coeff.

-

Quality Factors

Below are typical quality metrics for Fiber optic taper, final products may vary depends on the setup.

- Surface Quality: 40-20

- Surface Accuracy: 2λ (P-V)

- Max Shear Distortion: <40um

- Max Gross Distrotion: <65um

- Max Image Shift: <180um

- Max Barrel Distrtion: <3%

- Max Blemishes: < 90um

- Clear Aperture: 90% - 95%

-

Taper Height

- Taper Height: Taper Height approximately equal to the large end surface diameter.

For example, a taper with large end diameter of 30mm will have a height around 25~29mm.

*Note:This is not a definite value, could vary depending on the tapering process.

- Taper Height: Taper Height approximately equal to the large end surface diameter.

-

Customizable Specifications

These are the independent specifications you can change freely when customizing a Taper.

- Surface Size

- Shape

- Large End Fiber Diameter

- Magnification Ratio

Below are dependency specifications of the fiber optic taper. (Related to other properties, can't be changed independently)

- Small End Fiber Diameter

- Resolution

- N.A (Inherit from material)

- Transmission

-

Designing Tips

- Bigger surface will cost more than smaller surface. A surface diameter less than 50mm is good for saving the cost.

- Transmission is inherit from the material property and also related to the taper height.

- If you haven't use the Fiber Optic Taper before, consider to buy a stock unit from us to understand its performance better.

Product Configurations

Below are common configurations of the products. Most of the configuration below have been verified in applications.

Note:

1) Rect:Rect means both of the surface is rectangle shape.

2) Round:Round means both of the surface is round shape.

3) By Default, we will use 6um fiber (on the large end of the fiber optic taper).

4) By Default, the numerical aperture is 0.85 - 1.0 on the small end of fiber optic taper.

5) Discount is available for order quantity over 10pcs.

Applications

Below are some typical applications for Fiber Optic Tapers.

Beam Profiler

By integrating Fiber Optic Taper into the beam profiler, you can expand the sensory surface 2x - 3x easily.

- Compact Design (Compare with Lens)

- No Coma and Spherical Aberration

- Low Cost

- Easy Installation

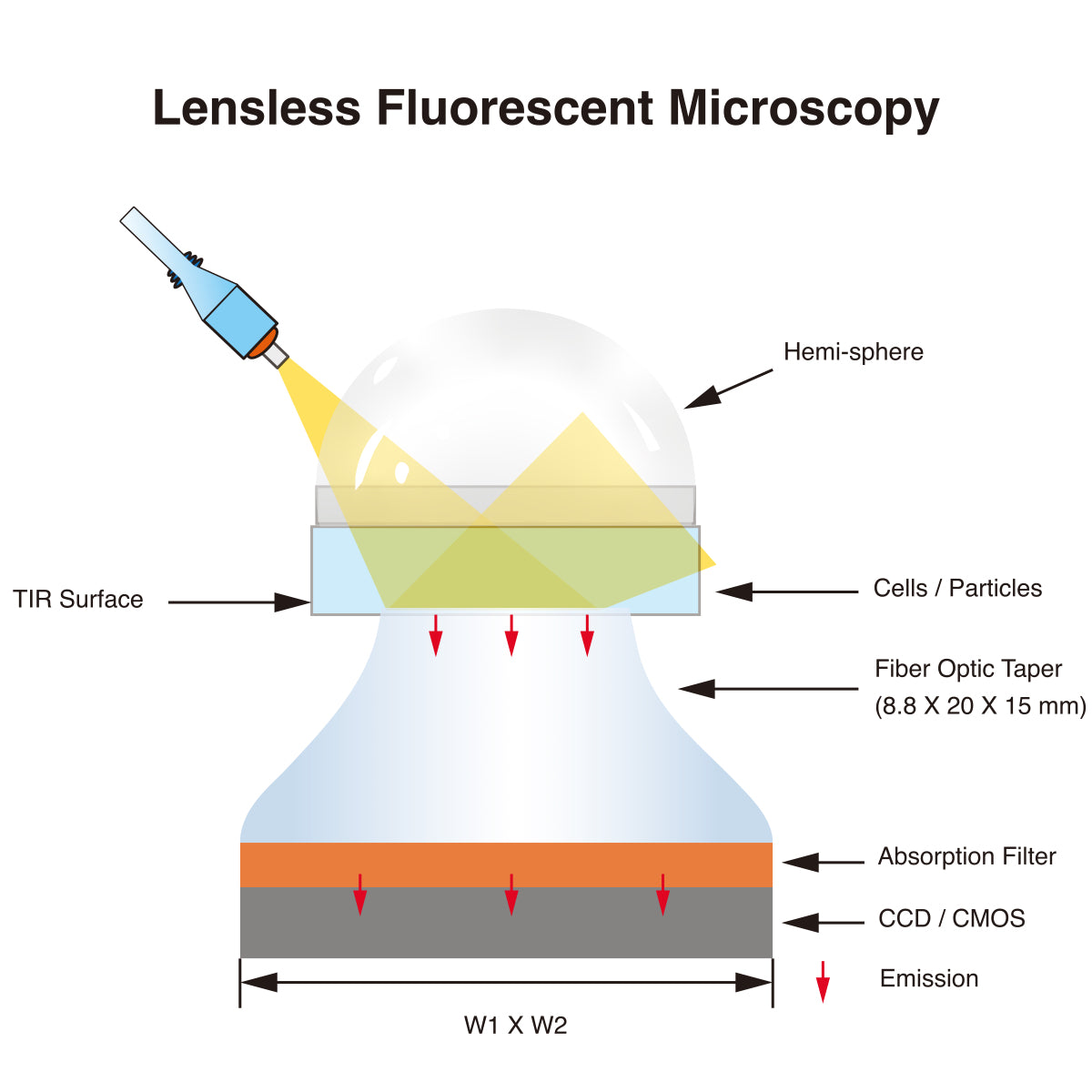

Fluorescent Imaging

Using Fiber Optic Taper in the Fluorescent Microscopy system you can increase the field of view of the microscope by capturing a larger area of the sample at the input end and projecting it onto a smaller area of the detector at the output end. This can improve the throughput and efficiency of the imaging system.

- Reduce Aberrations and Distortion

- Enhance Contrast

For more information, you can refer to the following web sources:

FAQs for Fiber Optic Taper

Why to use Fiber Optic Taper?

Fiber optic tapers have some advantages over conventional lenses, such as no need for focusing, high resolution, low weight, and . However, they also have some limitations, such as reduced numerical aperture, increased angular distribution of light, and sensitivity to mechanical stress and temperature changes.