What is Fiber Optic Plate (FOP)?

Fiber optic plate (FOP) is a component made of fused coherent fibers. It can precisely transmit image from input surface to output surface.

FOP can be used as Optical Isolator and Filter; it can absorb stray light during transmission and improving the SNR (signal to noise ratio).

FOP can be also used as a substrate of Xray Scintillator. It can absorb the excessive radiation which could do harm to the sensor.

In some other cases, FOP can used as coupler for complex design. for example: extraction image from a curve plane to a flat sensory surface.

Advantage of Fiber Optic Plate

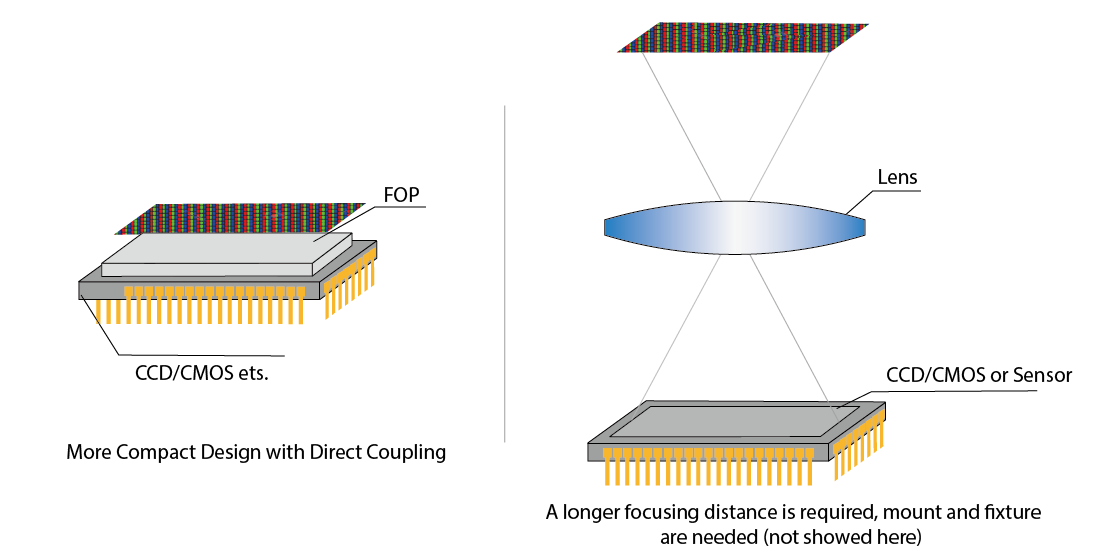

With fiber optic plate, you can directly coupling image plane to the sensory surface. With this setup, light efficiency is improved, and save up more spaces for the apparatus. However, it is possible to acheive better image quality with a multiple lens system. But the price will be significantly higher than Fiber Optic Plate. (And also the weight).

The cost of Fiber Optic Plate

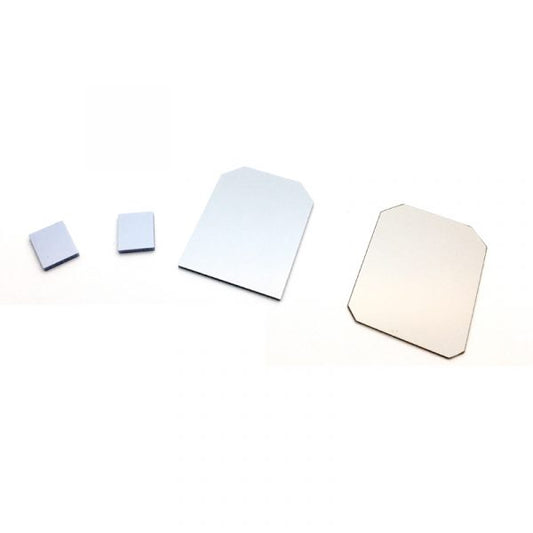

The price of fiber optic plate heavily depends on its geometry dimension and fiber(element) configuration.Usually, fiber optic plate under Ø25mm (diagonal) will quite affordable. The price could range from 5-15usd depending on the configuration.And the price could be further reduced in a large quantity (e.g : 10K pcs)However, when the dimension goes beyond Ø100mm, the price will be increased a lot. (e.g: 1,000 US dollars+)

Getting start with Fiber Optic Plate

We strongly recommend buying some cheapy in-stock FOPs from us. Which can help you understand better about its characteristics.We recommend below sample for initial test:– Ø25mm Round Sample (4-6um mono Fiber size)– 10mm x 10mm Square Sample (4-6um mono Fiber Size)

Variants of Fiber Optic Plates

-

Standard Fiber Optic Plate(sFOP)

Regular price From $250.00 USDRegular priceUnit price / per -

Low Numerical Aperture Fiber Optic Plate (lnaFOP)

Regular price From $112.00 USDRegular priceUnit price / per -

Dental X-Ray Fiber Optic Plate(dxFOP)

Regular price From $293.00 USDRegular priceUnit price / per -

Radiation Hardening Fiber Optic Plate(rhFOP)

Regular price From $195.00 USDRegular priceUnit price / per

Applications of Fiber Optic Plates

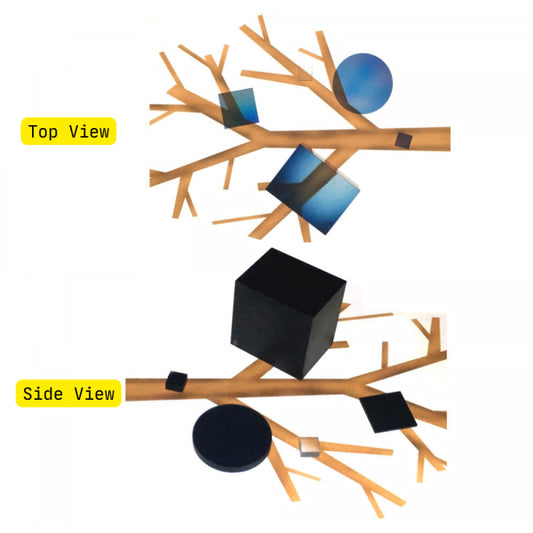

Intra-Oral Dental Sensor

Intraoral radiography is the most common type of radiographs among dental x-ray exams. It helps to detect decay between teeth and changes in the thickness of bone caused by gum disease as well as to identify the details of the upper and lower teeth in one area of the mouth. The most commonly used X-ray detectors for intraoral radiography is CsI(Tl) scintillation-based complementary metal–oxide–semiconductor (CMOS) photosensor array coupled with a fiber optic plate (FOP). The main purpose of the FOP is to absorb the x-ray which is not converted to visible light when traveling the scintillator. However, the x-rays happen to directly hit the CMOS photosensor due to incomplete absorption of the x-rays within the FOP. Approximately 0.3% among the incident x-rays at 70 kVp can be transmitted to CMOS sensor.

High Speed X-Ray Imaging

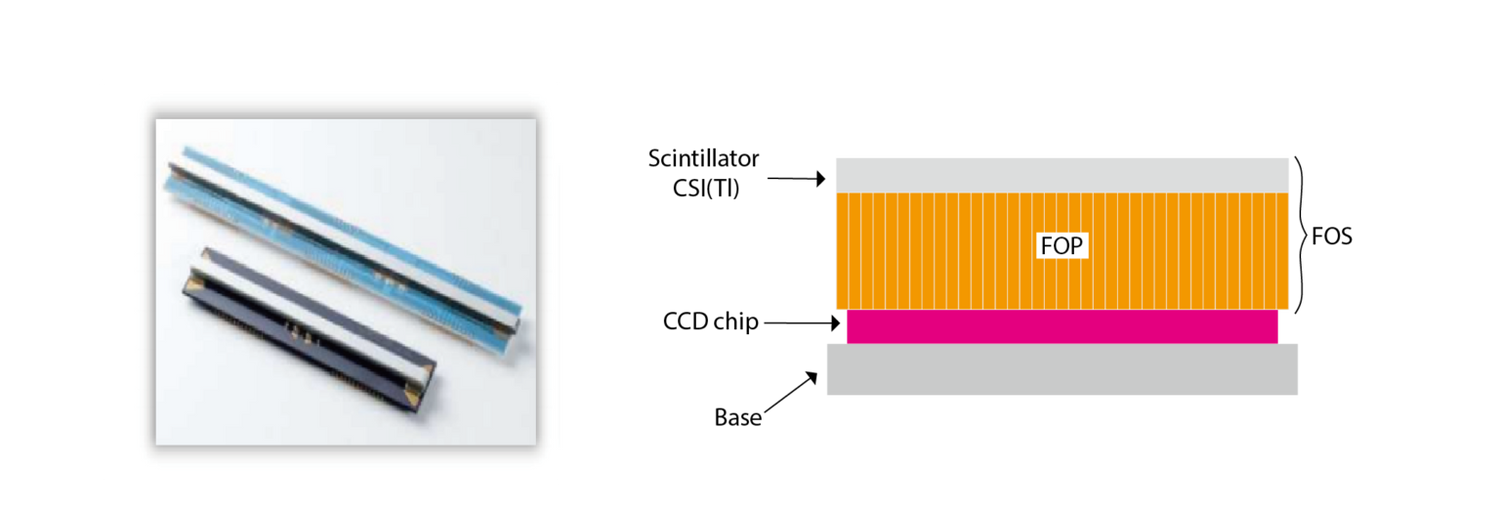

X-ray detectors based on scintillators do not exist only as solid-state screens up to a size of 440mm x 440mm but also as semiconductor device where firstly the X-ray energy is converted into visible light, which is then converted into electrical signals. Figure below shows the photo of a CCD image sensor (1536 x 128 pixel) and the physical principle of the basic structure of an X-ray image detector based on scintillator material like CsI:Tl and light guides with aluminum walls. A fiber optic plate (FOP) with a CsI:Tl scintillator (FOS) is directly coupled to the CCD image sensor delivers up to 15 frames per second with a spatial resolution up to 6 Lp/mm.

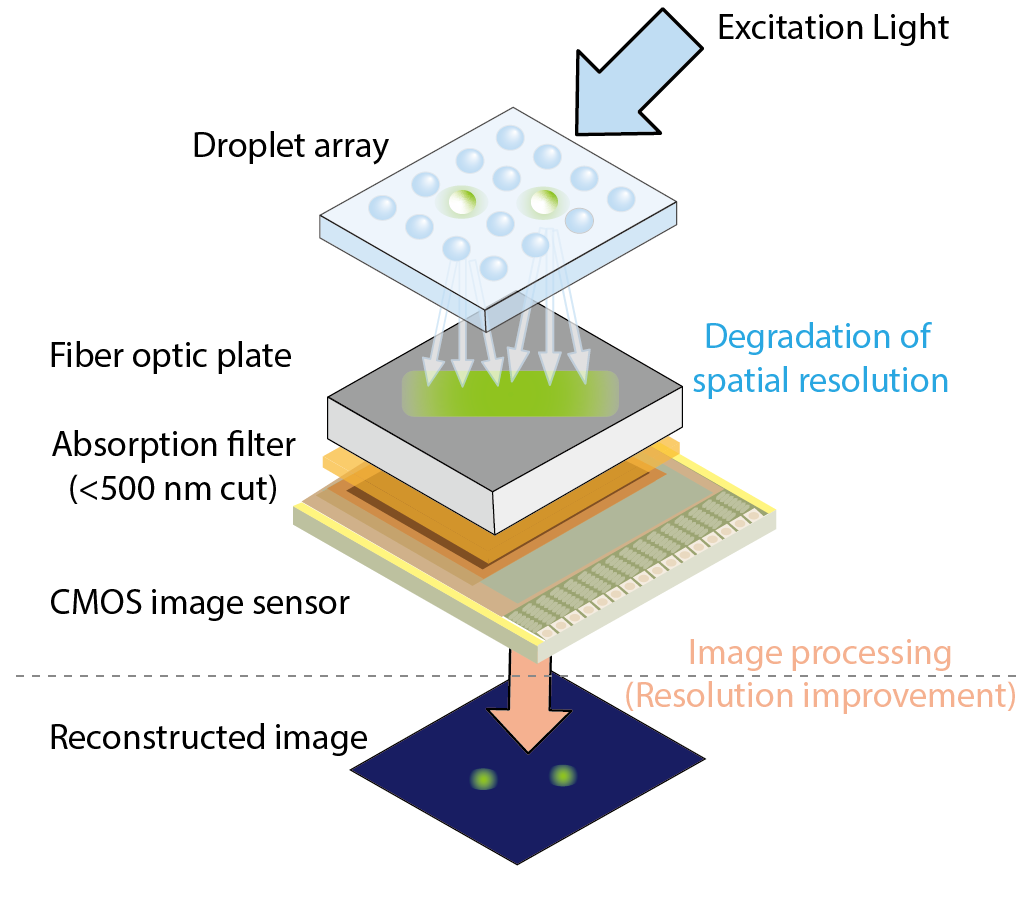

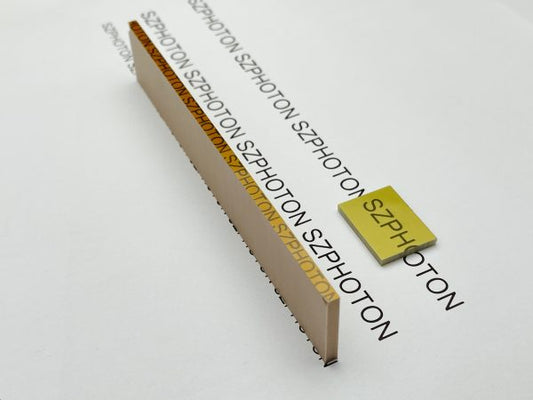

Fluorescence imaging

In the fluorescent imaging mode, the excitation light via a prism is reflected by total internal reflection (TIR) on the bottom of the glass substrate of a specimen. Some portion of the excitation light is scattered in the specimen on the surface of the droplets, microbeads, and glass substrates. These scattered light may not satisfy the TIR condition. To eliminate the scattered component, a yellow absorption filter is coated on the sensor. This filter is based on yellow dye and UV-curable polymer and the thickness is approximately 20 µm. Because the filter layer is fragile, a fiber optic plate is put on the device to protect the surface of the filter without degradation of spatial resolution.