小型高出力産業用ファイバーレーザー向け高集積クラッドモードストリッパーアレイ

引用

Liu, Y.; Wu, W.; Zhao, P.; Huang, S.; Li, Y.; Li, Y.; Li, M.; Tao, R.; Lin, H.; Wang, J. (2022).コンパクトな高出力産業用ファイバーレーザー向け高集積クラッドモードストリッパーアレイ. マイクロマシン、 13 (12)、2226。https ://doi.org/10.3390/mi13122226

キーワード

- 高出力産業用ファイバーレーザー

- クラッディングライト

- ポンプライト残留物

- 信号光漏れ

- 熱の問題

- 水冷ハウジング

- 小型化

- スペース削減

- 減量

- N-CMSアレイ

- オフセット配置

- レーザーの注入方向を反転する

- エッチング部分の移動

- 熱放散

- 出力対容積比

- マスター発振器電力増幅器(MOPA)

- 化学エッチング

- 二重クラッドファイバー(DCF)

簡単な

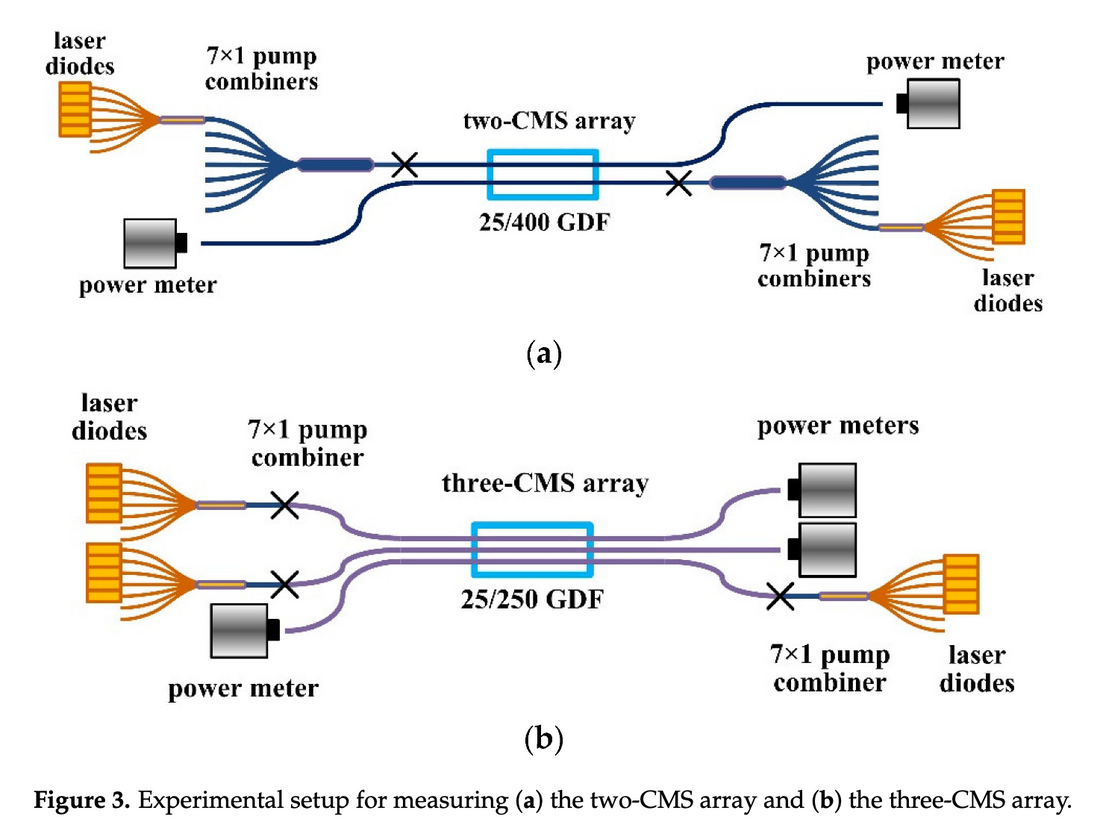

この記事では、ファイバー レーザー用の高度に統合されたクラッド モード ストリッパーのアレイを提案し、実証します。このアレイは、複数の CMS を 1 つのデバイスにまとめ、熱を効果的に管理することで、スペースと重量を削減します。

まとめ

本稿では、複数のクラッドモードストリッパー(CMS)を単一のデバイスに統合し、コンパクトな高出力ファイバーレーザーを実現する設計を提案する。最も高温の光除去領域をずらして配置することで、統合型CMSアレイは、著しい熱蓄積や相互影響なしにフルパワーで動作可能となり、 2つのCMSアレイと3つのCMSアレイでそれぞれ50%から66%のスペースと重量削減を実現する。かさばり高温となる部品の小型化は、産業用ファイバーレーザーにおける体積当たり電力比の向上に貢献する。

出典: https://www.mdpi.com/2072-666X/13/12/2226