Specifications

-

(Large End) Fiber Diameter

The fiber size on large end of the taper

- Typical Value: 6.0um / 10.0um

- Min Value: 4.0um

- Max Value: 15.0um

*Note: The fiber diameter is different on big end and small end.

-

(Small End) Fiber Diameter

The fiber size on the small end of the taper.

*Note: This is a dependency value, which related to Magnification ratio and Large End Fiber Diameter

- Typical Value: ≥2.5um

- Min Value: 2um

- Max Value: NA

-

Magnification Ratio

Key Parameter of Fiber Optic Taper. Defines the Magnifying power of the component.

- Typical Value: 1.5x-3x

- High Value: 3.1x- 7.0x

*Note:

- Higher magnification ratio may reduce the light transmission further.

- FOT with 3X magnification usually needs customization.

-

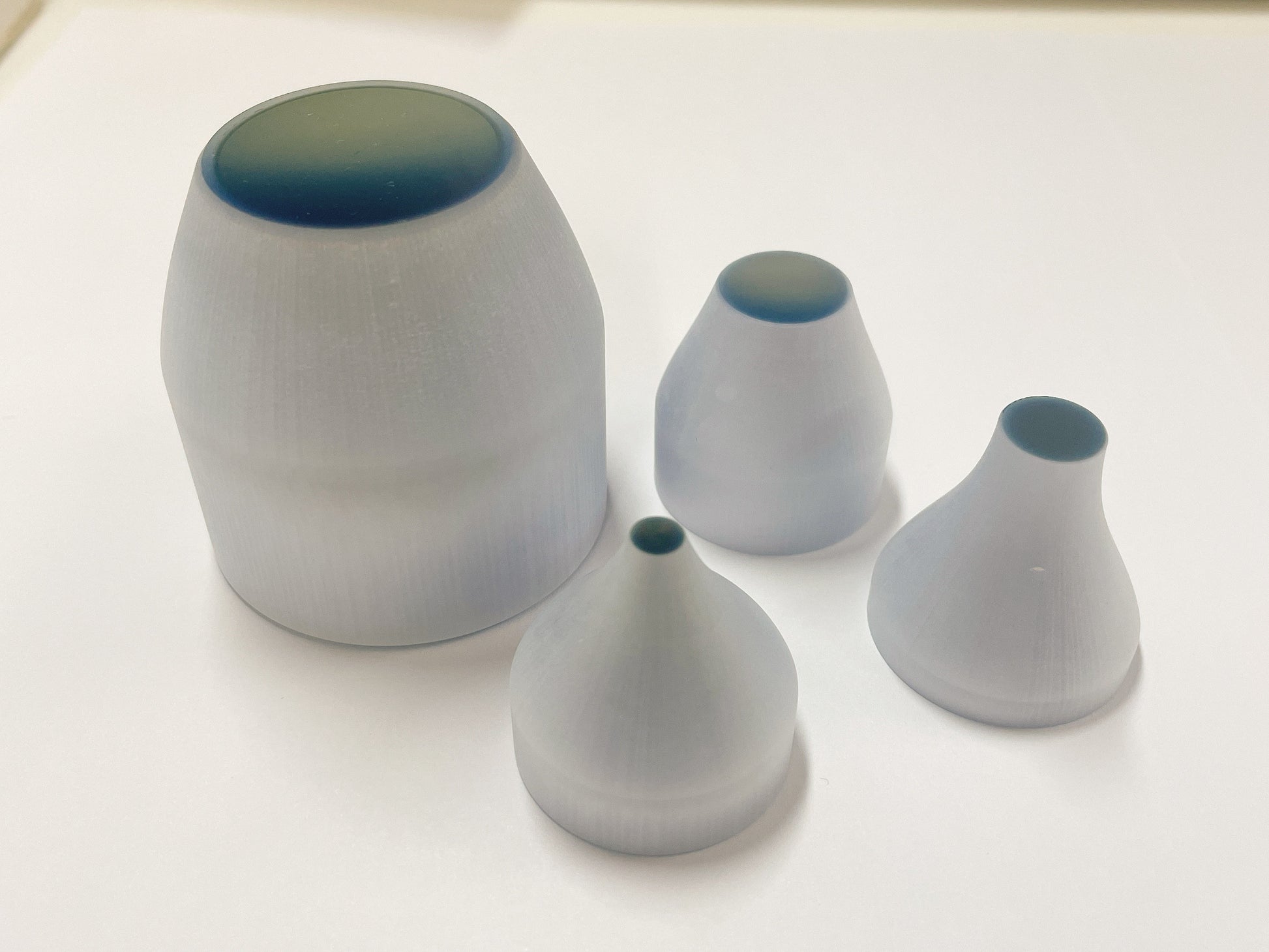

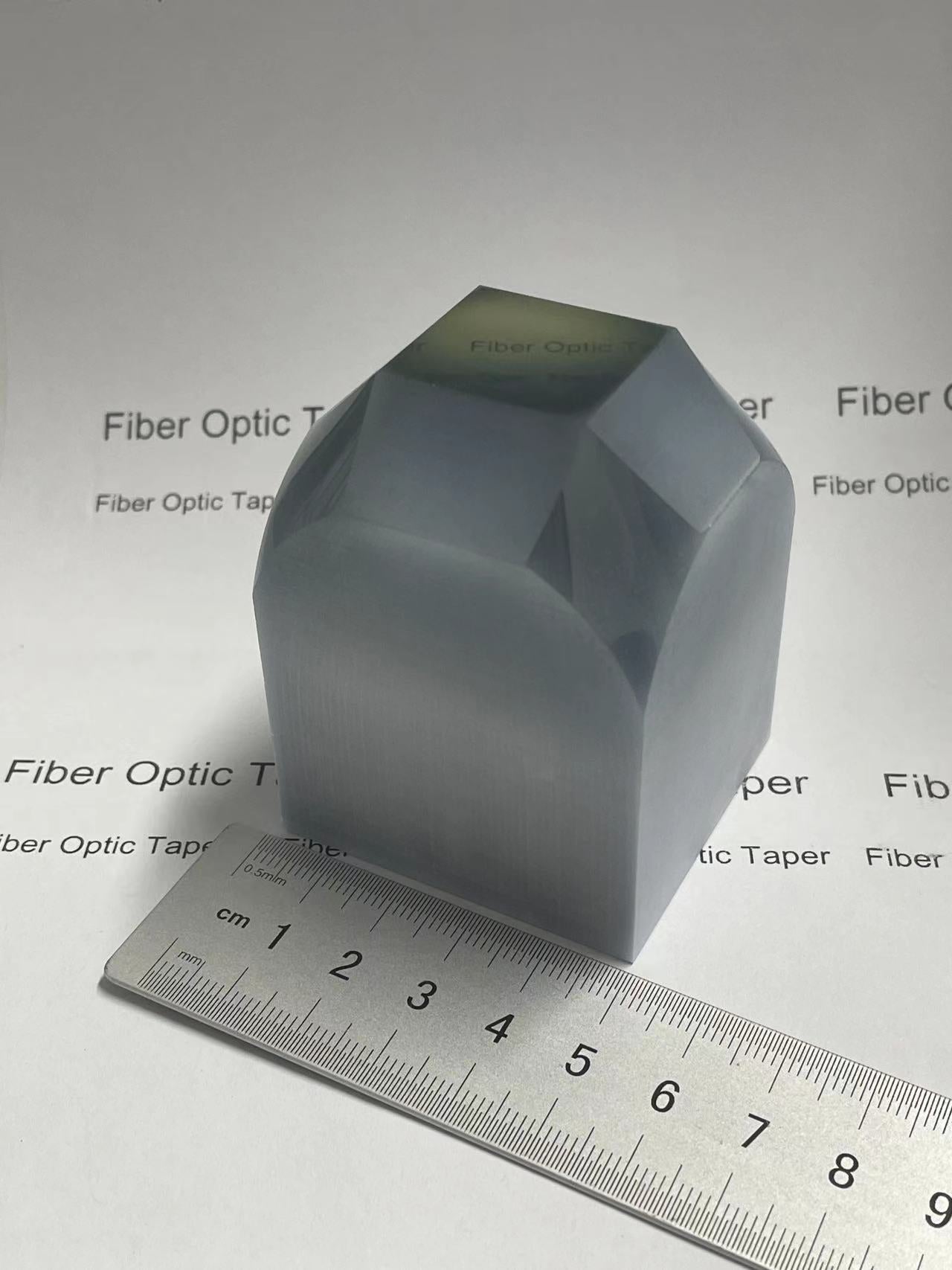

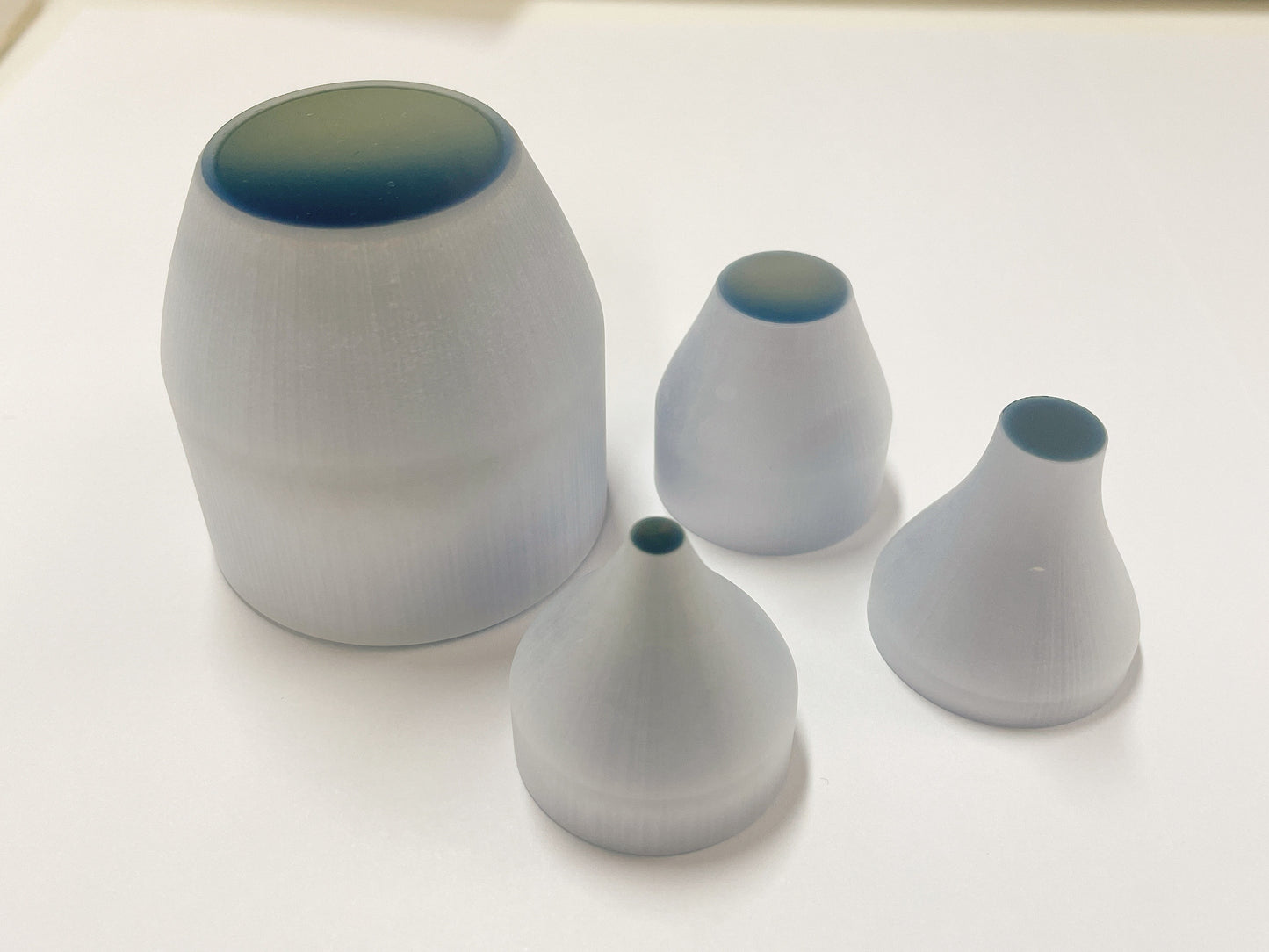

Shape of FOT

The geometric of Large end and Small end of the Fiber Optic Taper.

Typical Shapes:

- Round to Round

- Square to Square

Availablility: Square, Round, Step, Concave

-

Numerical Aperture (N.A)

The numerical aperture (NA) for fiber is a measure of the range of angles within which light that is incident on the fiber will be transmitted along it.

- Theorical Value: 1

- Practical Value: 0.65 - 0.85

*Note:The numerical aperture here is referred to N.A on small end.

-

Resolution

The resolution here is expressd in the terms of lp/mm.

Typical Value:

- 50lp/mm (10um)

- 102lp/mm (6um)

- 166lp/mm (3um)

- 230lp/mm(2um)

*Note:Testing with USAF1951, all results are under theoretical testing condition.

"lp/mm" is a pair of black and white squares in object space, which are the smallest elements that can be distinguished by the system.

-

Material Characteristic

- Thermal Expansion Coeff.

(20-300°)

= (60-90) x 10**(-7) / °C - Vacumm Tightness

< 10 - 12Pa · m3/s - Transmission (Collimated Light)

Approx 75 ~ 85% - Wavelength Range

400nm ~ 1400nm - Interestital Fibers (EMA)

Yes - XRAY Absorption

Yes

*Note:EMA are used to absorb the stray light inside the fiber optic taper.

- Thermal Expansion Coeff.

-

Quality Factors

Below are typical quality metrics for Fiber optic taper, final products may vary depends on the setup.

- Surface Quality: 40-20

- Surface Accuracy: 2λ (P-V)

- Max Shear Distortion: <40um

- Max Gross Distrotion: <65um

- Max Image Shift: <180um

- Max Barrel Distrtion: <3%

- Max Blemishes: < 90um

- Clear Aperture: 90% - 95%

-

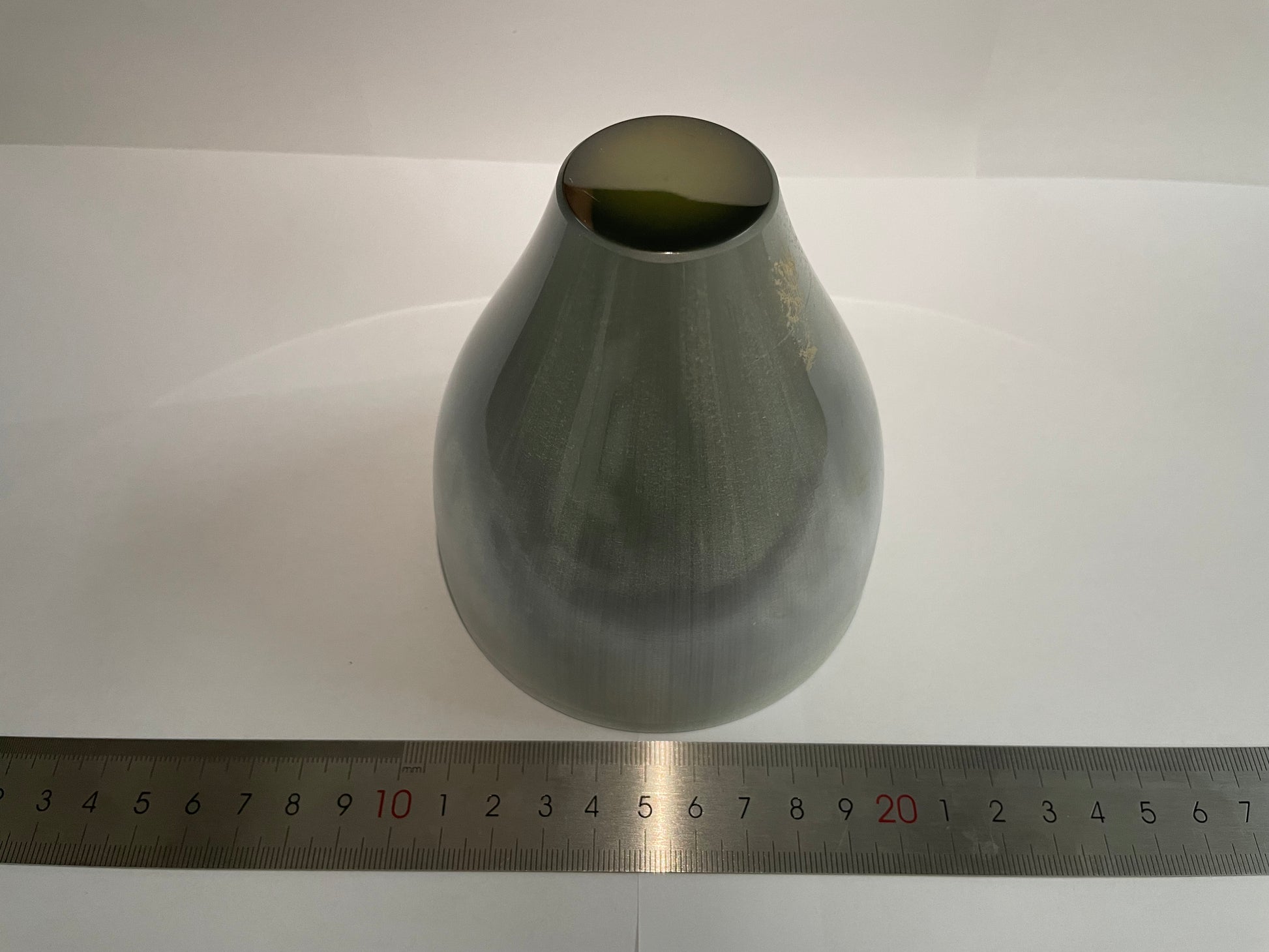

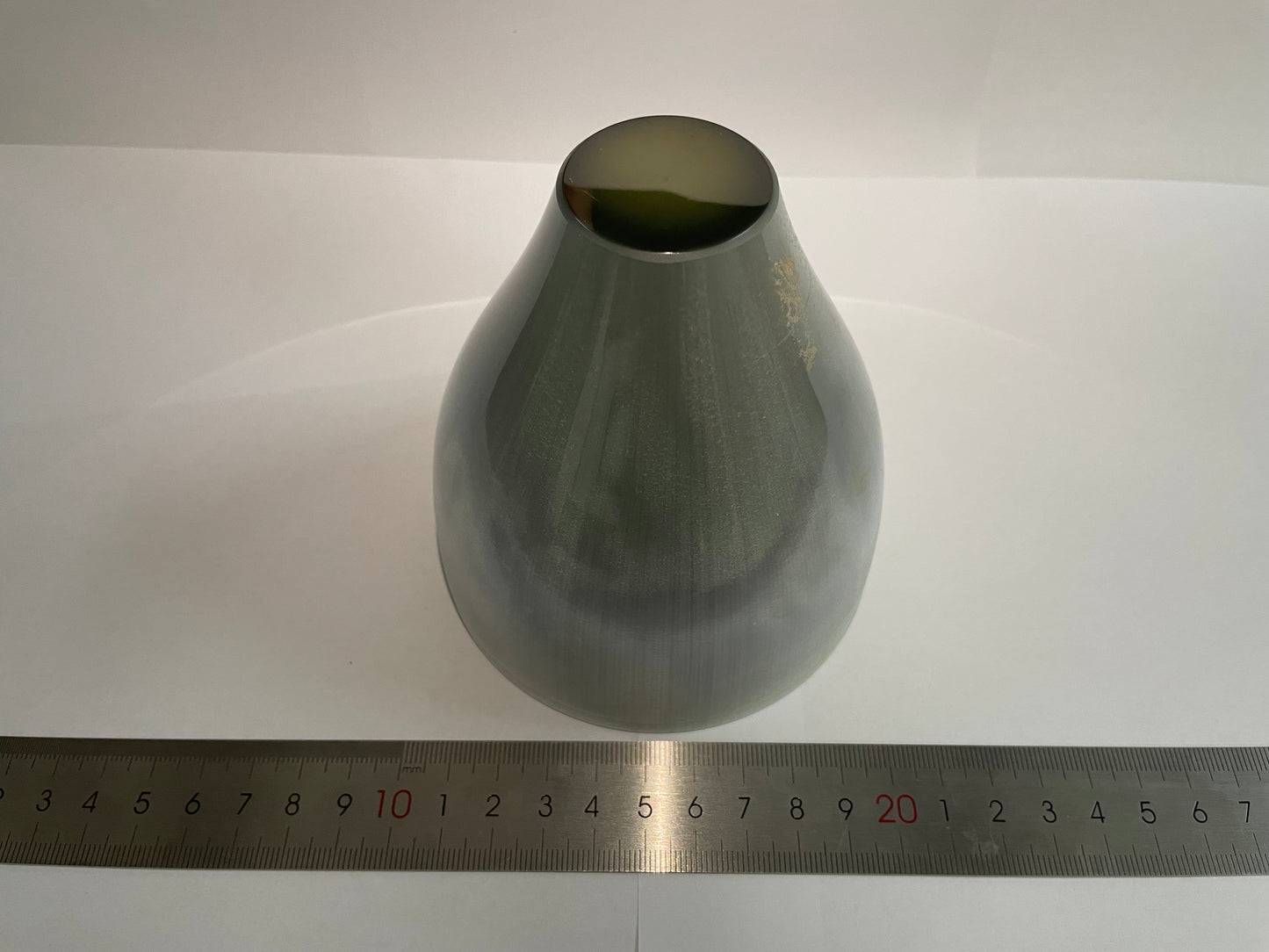

Height of the Taper

- Taper Height: Minimum Taper Height can be made to 0.8-1.0x of the Large End Taper Diameter

For example, a taper with large end diameter of 30mm will have a height around 24~30mm.*Note:This is not a definite value, could vary depending on the tapering process

-

Customizable Specifications

These are the independent specifications you can change freely when customizing a Taper.

- Surface Size

- Shape

- Large End Fiber Diameter

- Magnification Ratio

Below are dependency specifications of the fiber optic taper. (Related to other properties, can't be changed independently)

- Small End Fiber Diameter

- Resolution

- N.A (Inherit from material)

- Transmission

-

Designing Tips

- Bigger surface will cost more than smaller surface. A surface diameter less than 50mm is good for saving the cost.

- Transmission is inherit from the material property and also related to the taper height.

- If you haven't use the Fiber Optic Taper before, consider to buy a stock unit from us to understand its performance better.

-

Fiber Optic Taper with 7x Magnification Ratio

-

Fiber Optic Taper with 3x Magnification Ratio

-

Rectangle Surface Fiber Optic Taper

-

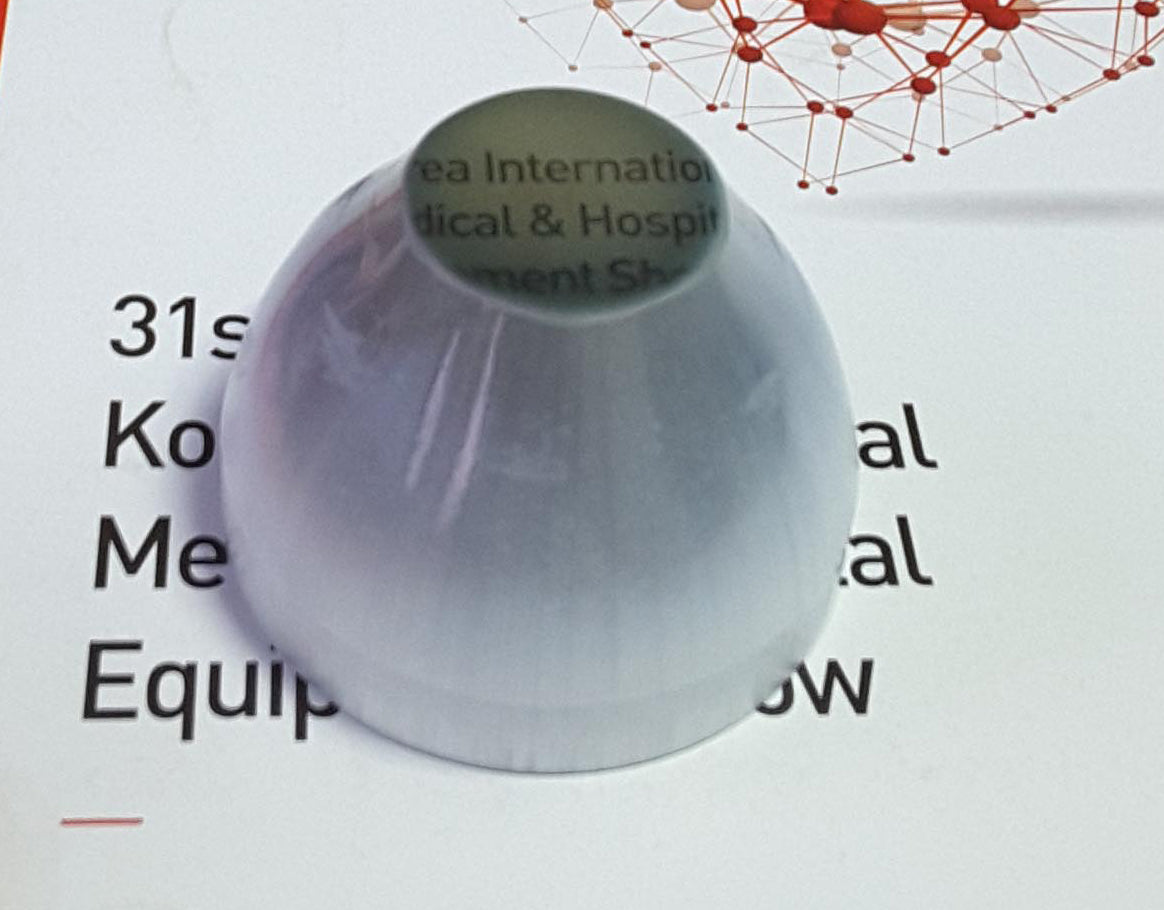

Fiber Optic Taper with Concave Surface

-

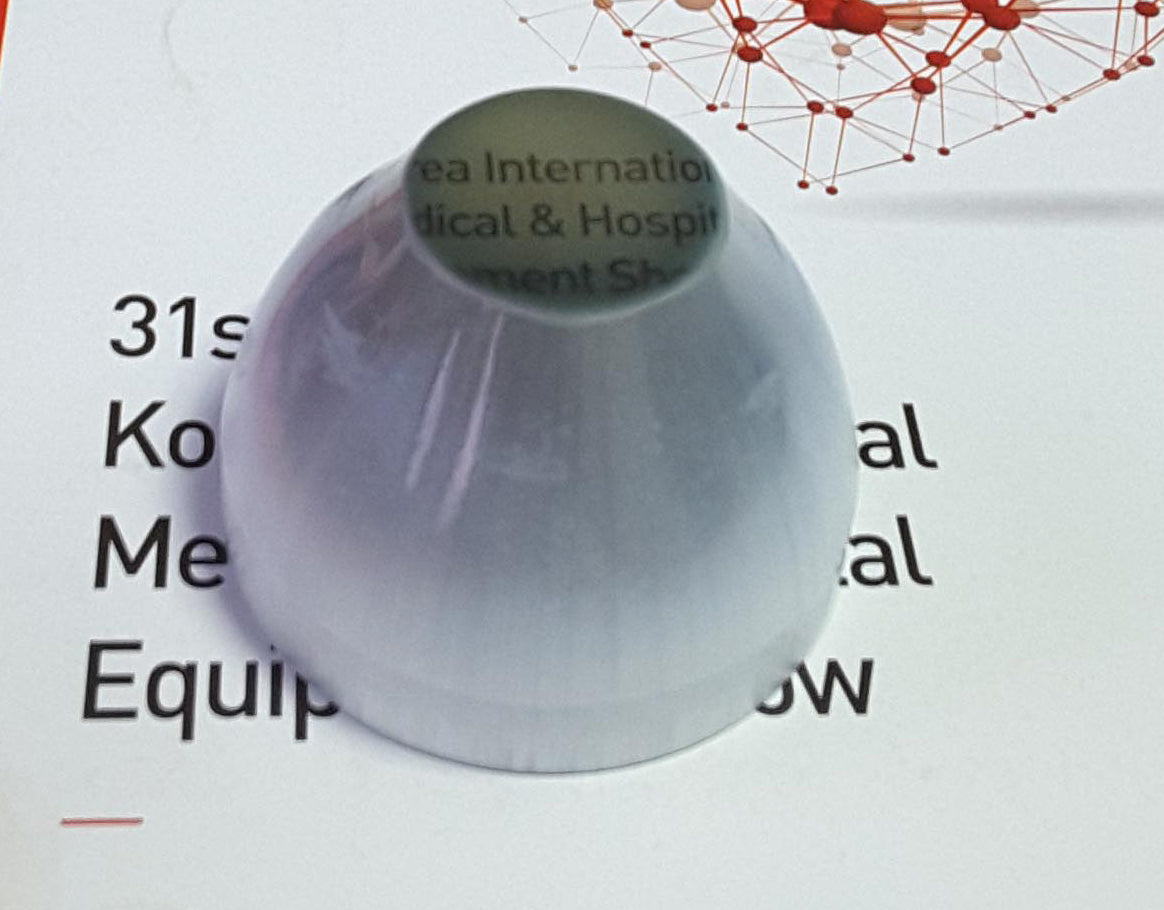

Different Material (Top View)

-

Different Material (Side View)

-

Different Material (Bottom View)

-

Beam Profiler

By integrating Fiber Optic Taper into the beam profiler, you can expand the sensory surface 2x - 3x easily.

- Compact Design (Compare with Lens)

- No Coma and Spherical Aberration

- Low Cost

- Easy Installation

-

-

Fluorescent Imaging

Using Fiber Optic Taper in the Fluorescent Microscopy system you can increase the field of view of the microscope by capturing a larger area of the sample at the input end and projecting it onto a smaller area of the detector at the output end. This can improve the throughput and efficiency of the imaging system.

- Reduce Aberrations and Distortion

- Enhance Contrast

For more information, you can refer to the following web sources: