Theoretical and Numerical Analysis for Design of High Ratio Fiber Optic Taper Drawing Process

Citation

Jiahui Liu and Lili Zheng, "Theoretical and Numerical Analysis for Design of High Ratio Fiber Optic Taper Drawing Process", IEEE Photonics Journal, vol. 12, no. 6, Dec. 2020.

Keywords

- Fiber optic taper drawing

- neck-down profile

- computational modelling

- numerical simulation

Brief

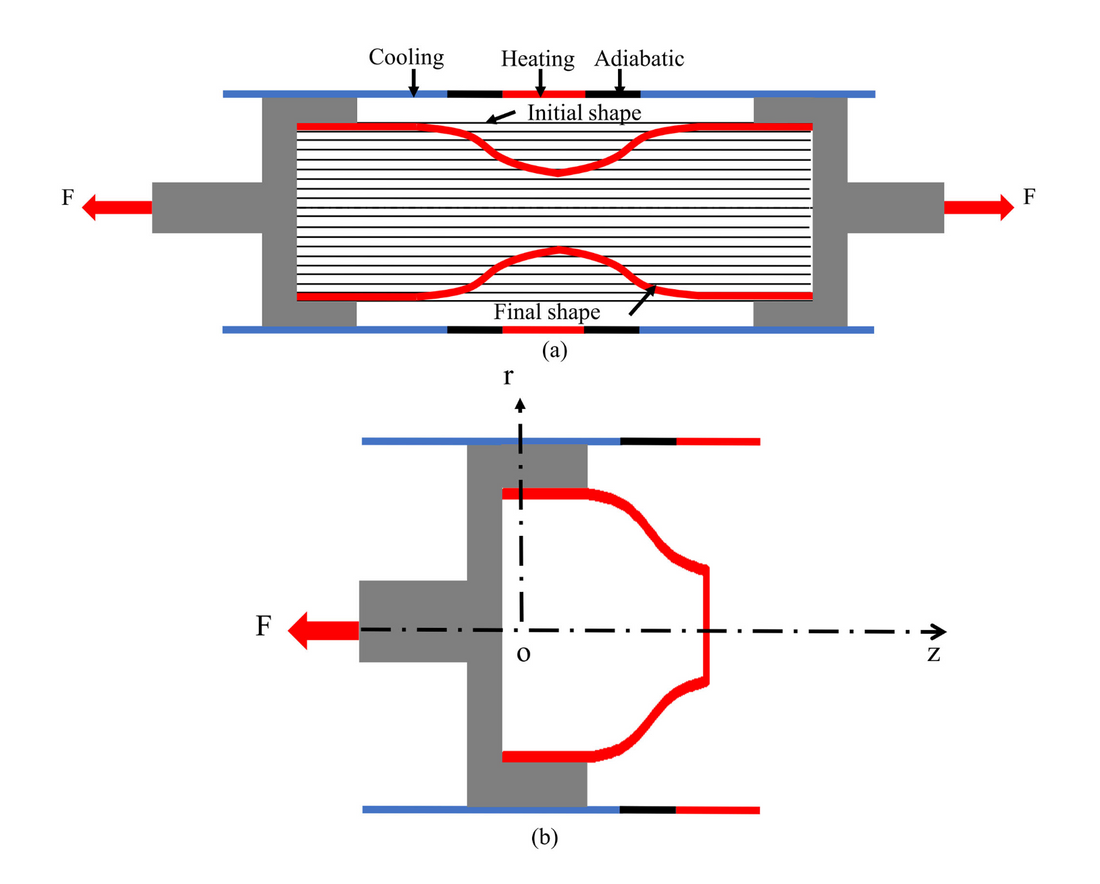

The final shape of a fiber optic taper is primarily determined by the material properties of the silica glass and the thermal design of the furnace, and is independent of the stretching conditions used during the drawing process. This article describes the development of a numerical method for predicting the shape evolution of large radius and high ratio fiber optic tapers during the drawing process. The model considers the 2D distributions of temperature, temperature-dependent viscosity, and radially integrated velocity. Researchers found that an adiabatic shield can be used in the furnace to concentrate heat in the middle of the taper and increase the temperature gradient, which helps accelerate the drawing process.

Summary

This 2020 IEEE Photonics Journal article by Jiahui Liu and Lili Zheng explores the fiber optic taper drawing process, which is used to manufacture fiber optic tapers. Fiber optic tapers are optical components used in applications such as CCD coupling, television imaging, and night vision devices. The quality of a fiber optic taper, particularly its shape, significantly impacts its transmission properties.

- The authors developed a numerical model to simulate the process and understand how various factors influence the final shape of the taper. Their findings suggest that:

- The viscosity of the silica glass used is crucial. Lower viscosity can speed up the drawing process but might result in a less desirable taper shape with a longer waist length.

- The temperature distribution within the furnace plays a vital role. A higher temperature in the furnace's hot region can lead to a faster drawing process and a steeper taper shape with a shorter waist length.

- The design of the furnace, specifically the lengths of the hot, adiabatic, and cold regions, also impacts the taper shape.

- Incorporating adiabatic shields near the hot region boundary can improve heat concentration, leading to a faster process and a more desirable taper shape with a larger slope.

- While the external force applied during the drawing process affects the deformation rate of the taper, it does not significantly impact the final shape of the taper.

The authors conclude that by understanding these factors and using their model, manufacturers can optimize the fiber optic taper drawing process to produce high-quality tapers with desirable shapes for various applications.

Origin: https://ieeexplore.ieee.org/ielx7/4563994/9233471/09263305.pdf