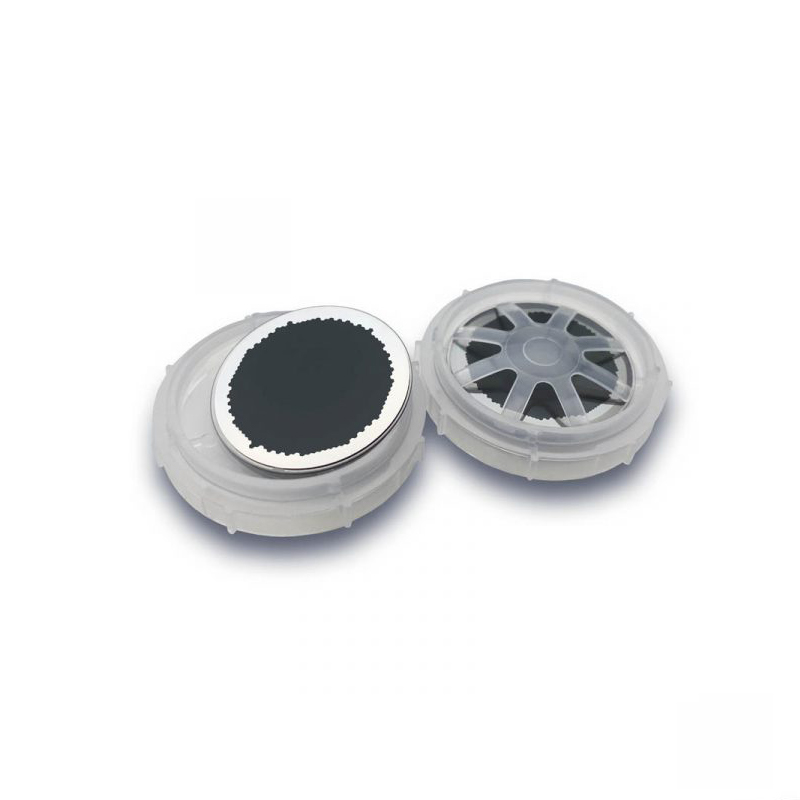

Microchannel Plate (MCP)

Microchannel Plate (MCP)

Couldn't load pickup availability

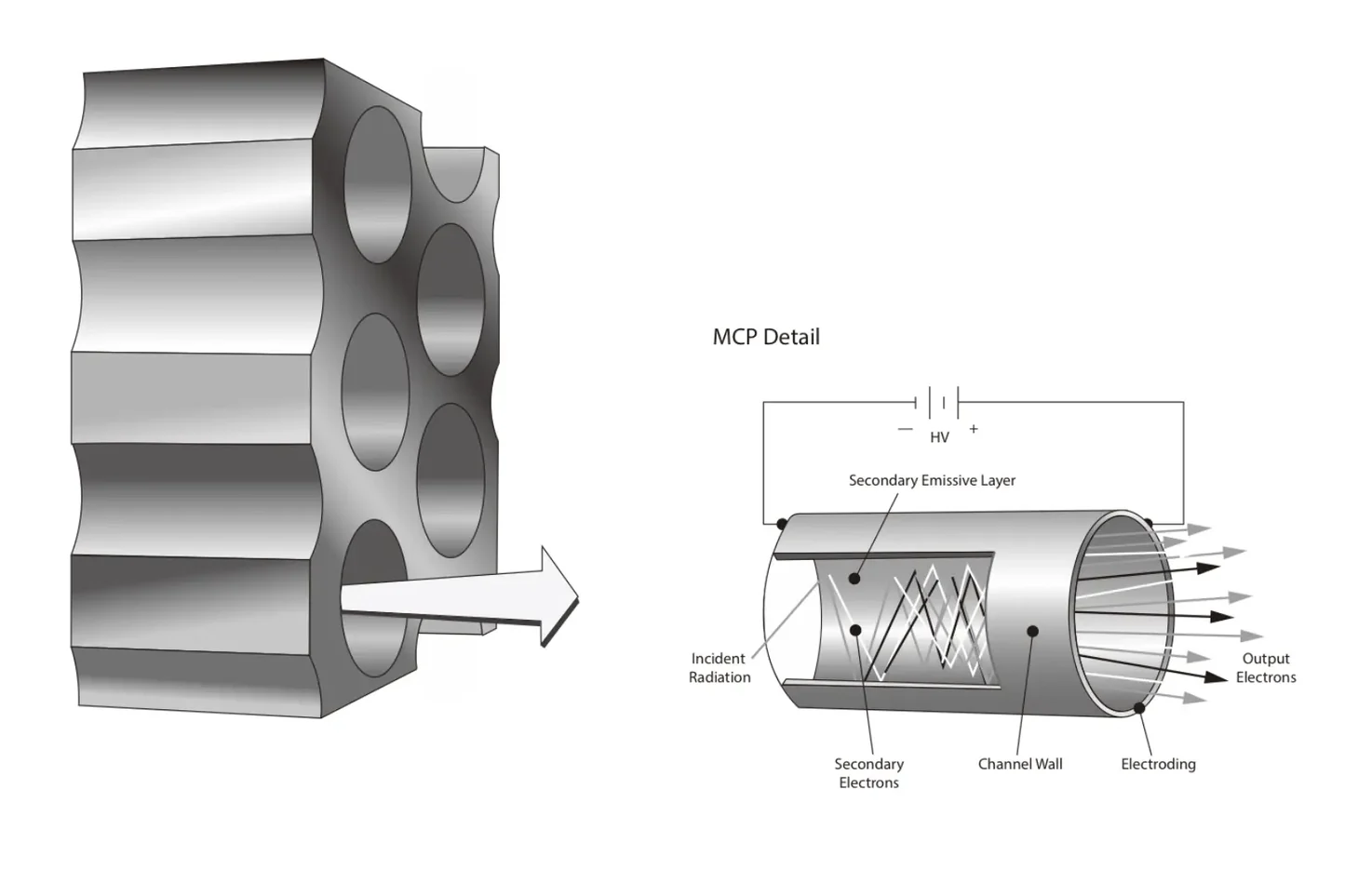

A Microchannel Plate (MCP) is a device that can amplify single particles (such as electrons or ions) or photons (such as ultraviolet or X-rays) by using many tiny tubes that multiply electrons through secondary emission. It is often used in intensified cameras to make weak images and signal stronger and more detectable.

Specifications

-

Dimension of MCP

Typical Pore Size of MCP (D)

- 6um,8um,10um,12um

Typical Thickness (L)

- 0.3-0.5mm

Typical Outer Diameter of MCP

- dia16mm

- dia25mm

- dia33mm

- dia50mm

-

L/D Ratio

Length of the MCP is nearly equal to the thickness of the channels.

- Typical Range: 40 - 60

The ratio of the channel length (L) to channel diameter (d) is L/D ratio.

Gain of the MCP is highly related with the L//D ratio.

-

-

Stacking the MCPs

The ratio of the number of output electrons to the number of input particles or photons that measures the amplification factor of the plate.

- Typical Gain for 1 Stage:

10^3 - 10^4 - Typical Gain for 2 Stages (Chevron): 10^6

- Typical Gain for 3 Stages

(Z-Stack): 10^7 - 10^8

- Typical Gain for 1 Stage:

-

Bias Angle

The angle between the normal direction and the axis of the microchannels that influences the probability of secondary emission and gain uniformity of the plate.

Typical Value:

- 6° / 8° / 10° / 12°

-

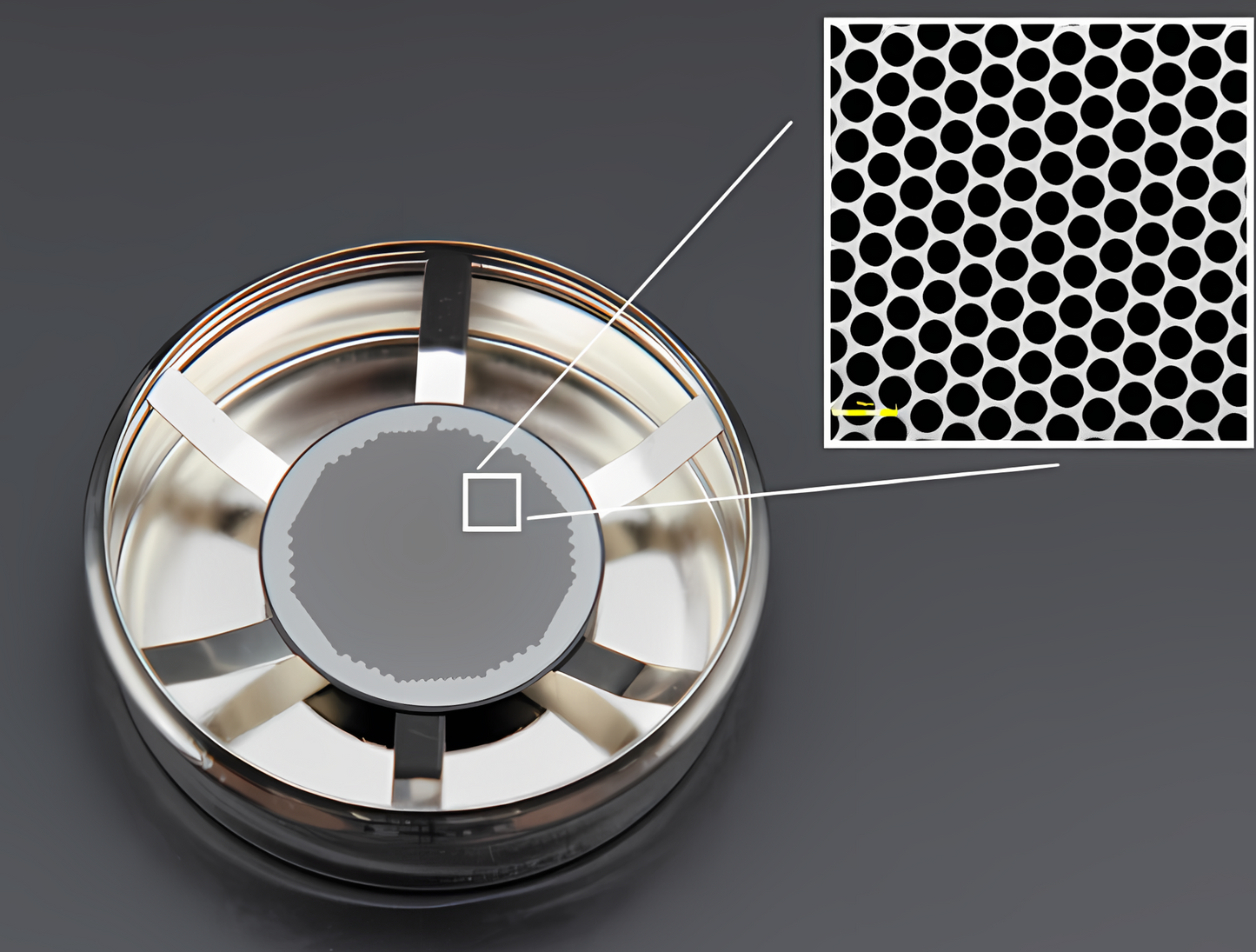

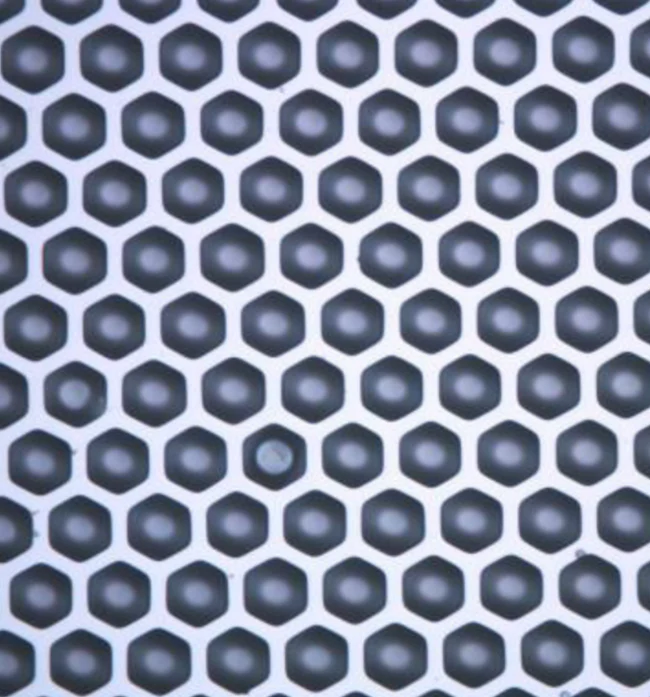

Open area ratio (OAR)

The ratio of the total area of the microchannels to the active area of the plate that indicates the fraction of incident particles or photons that can enter the channels.

Typical Range:

- 55% - 65%

-

Fabrication & Materials

MCPs is produced from a special made fiber optic plate. After acid etching the core part. Leaving million of pore on the plate.

Substrate Material

- Leadsilicate Glass

- Ni-Cr (Nickel-Chromium)

-

Resistance

The resistance is the electrical resistance of the MCP material, which affects the voltage and current required to operate the MCP.

- Typical Value: 50MΩ - 200MΩ

-

End Spoiling

End spoiling refer to the electrode coating go inside the MCP pore. There are input and output side end spoiling

-

Image Intensifiers

Image intensifiers use a MCP to amplify low-light images, such as night vision or fluorescence microscopy. The input photons are converted to electrons by a photocathode, then multiplied by the MCP, and finally converted back to photons by a phosphor screen.

-

Working Principles

A fully functional MCP detector may contains the following components:

- A photocathode: This is a thin layer of material that converts the incident photons into primary electrons by the photoelectric effect. The photocathode is attached to the input window of the MCP and biased with a negative voltage.

- A microchannel plate: This is a thin wafer of glass or ceramic that contains millions of microscopic tubes (microchannels) that run parallel to each other and are perpendicular to the input and output surfaces. The inner walls of the microchannels are coated with a material that emits secondary electrons when struck by the primary electrons. The microchannels are also biased with a high voltage that accelerates the electrons towards the output end. As the electrons travel through the microchannels, they collide with the walls and produce more secondary electrons, creating a cascade of amplification.

- An anode: This is a metal layer that collects the amplified electrons from the microchannel plate and converts them into an electrical signal. The anode can have different shapes and configurations depending on the application. For example, it can be a single metal sheet, a resistive layer, a segmented array, or a phosphor screen. The anode can also provide spatial resolution by mapping the position of the incident photons on the photocathode.

- When a photon hits the photocathode, it ejects a primary electron with a certain energy and direction.

- The primary electron enters the microchannel plate and is accelerated by the electric field towards the output end.

- As the primary electron travels through the microchannel, it collides with the channel wall and emits one or more secondary electrons.

- The secondary electrons are also accelerated by the electric field and collide with the channel wall, producing more secondary electrons. This process repeats until the electron avalanche reaches the output end of the microchannel.

- The output electrons are collected by the anode and converted into an electrical pulse that corresponds to the incident photon.