Glass Capillary Array (GCA)

Glass Capillary Array (GCA)

Couldn't load pickup availability

Glass Capillary Array (CA) is a product that consists of millions of hollow fibers fused together to form a uniform and rigid structure. The tubes, or capillaries, have very small diameters and can be used for various purposes such as filtration, collimation, beam splitting, and multiplexed analysis. Glass Capillary Array can be made in different shapes, sizes, materials, and surface finishes depending on the application. They have high heat resistance, mechanical strength, optical quality, and chemical stability.

Specifications

-

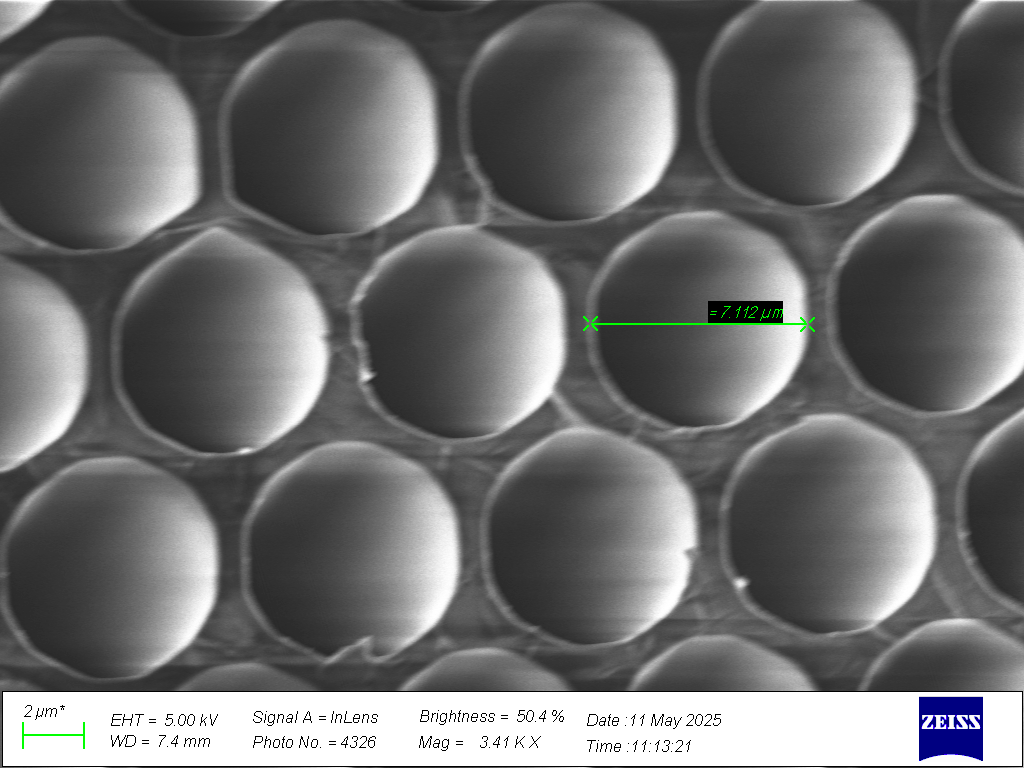

Hole Diameter

Hole diameter is the diameter of each Single Capillary (hole).

- Typical Value: 4um,6um,25um,100um

- Min Value: 1um

- Max Value: 200um

The hole diameter influences the sample volume, the electric field strength, and the heat dissipation.

-

Length to Diameter Ratio (L/D)

L/D ratio in capillary array is the ratio of the length to the diameter of the capillaries.

- Typical Value: 50 - 200

- Max Value: 600

A longer and thinner capillary may require more sophisticated fabrication techniques and materials, which can increase the production cost and complexity

-

Open Area Ratio (OAR)

OAR ratio is the open area ratio of a capillary array, which is defined as the ratio of the cross-sectional area of the capillaries to the total area of the array.

- Typical Range: 50% - 65%

- High Range: 70% - 80%

-

Format Available

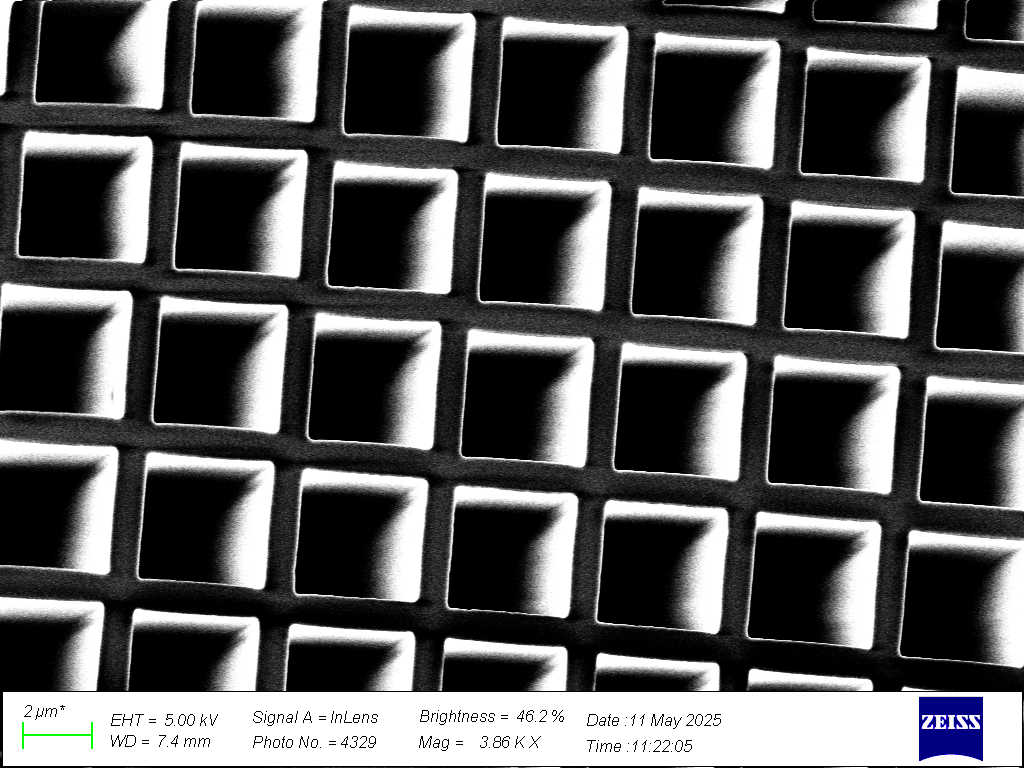

Single Capillary (Hole) Shape

- Circular

- Rectangle

Array Shape Available:

- Circular

- Rectangle

Array Dimension

- Typical: dia25mm - dia50mm

- Max: dia200mm

- Min: dia6mm

-

Material & Fabrication

- Material: Borosilicate Glass

- Heat Resistance: up to 500°C

- Lead Free: Optional

(Hole shape and uniformity may vary depends on materials) - Surface Coating Available: Ni-CR, ITO

- Interal Coating(on wall): ITO, TiO2

-

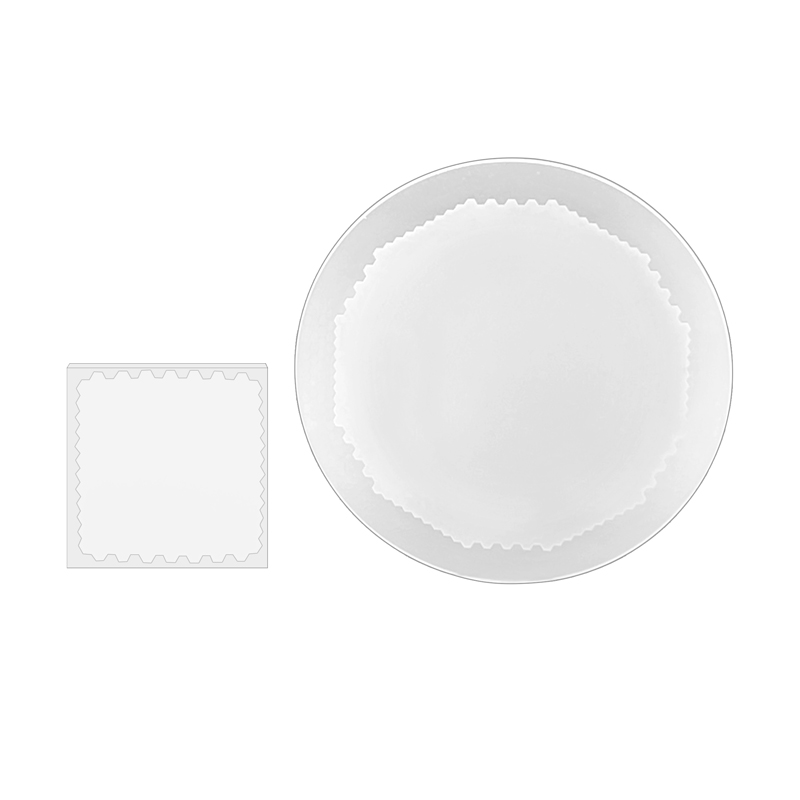

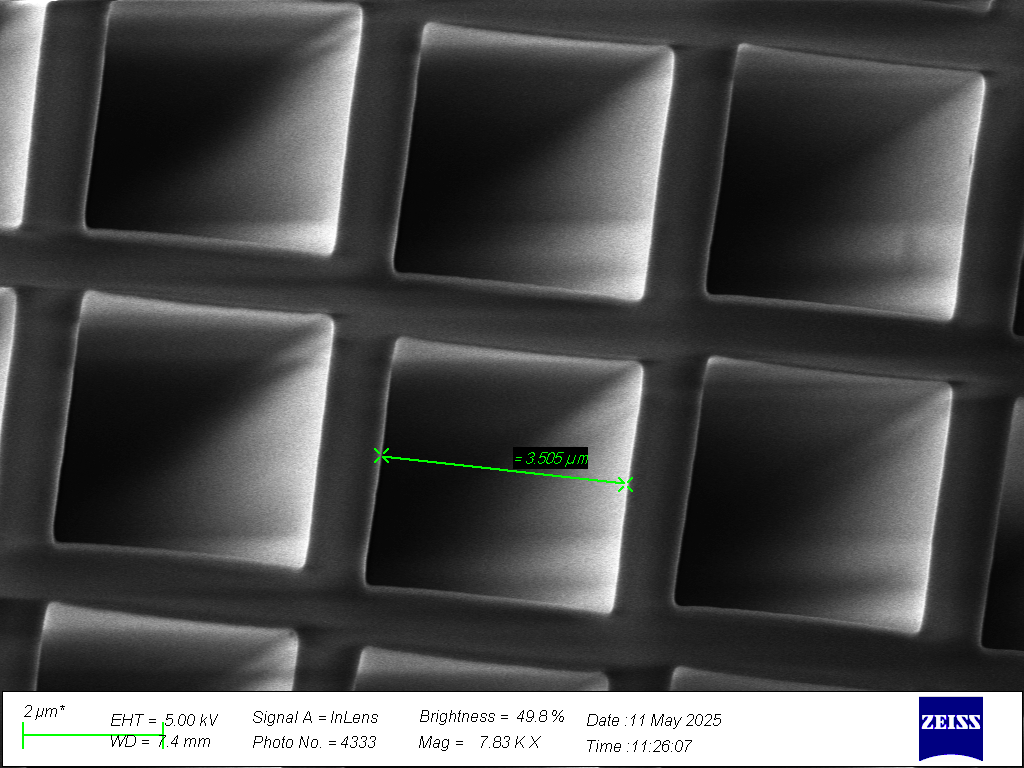

Cross Section View of GCA

-

750x Magnification

-

1500x Magnification

-

3000x Magnification

-

3750x Magnification