Development of thin quartz glass utilising through-glass-via (TGV) formation by dry etching technology

Citation

Tang, Y.-H., Lin, Y.-H., Shiao, M.-H., & Yu, C.-S. (2016). Development of thin quartz glass utilising through-glass-via (TGV) formation by dry etching technology. Micro & Nano Letters, 11(8), 492–496.

Keywords

- Through-Glass-Via (TGV)

- Dry Etching Technology

- Inductively Coupled Plasma Reactive-Ion Etching (ICP-RIE)

- Quartz Glass

- Interposer

- Three-Dimensional Integrated Circuit (3D-IC) Packaging

- Etching Rate

- Sidewall Angle

- Surface Topography/Morphology

- Hard Mask

- Electroplating

Brief

This article describes the fabrication process of through-glass-via (TGV) structures in thin quartz glass using inductively coupled plasma reactive-ion etching (ICP-RIE) for three-dimensional integrated circuit packaging technology.

Summary

This article, published in 2016 in the journal Micro & Nano Letters, details the development of thin quartz glass using a dry etching technique to create through-glass-vias (TGVs). The authors, Yu-Hsiang Tang et al., from the National Applied Research Laboratories in Taiwan, highlight the growing importance of 3D integrated circuit (3D-IC) packaging technology.

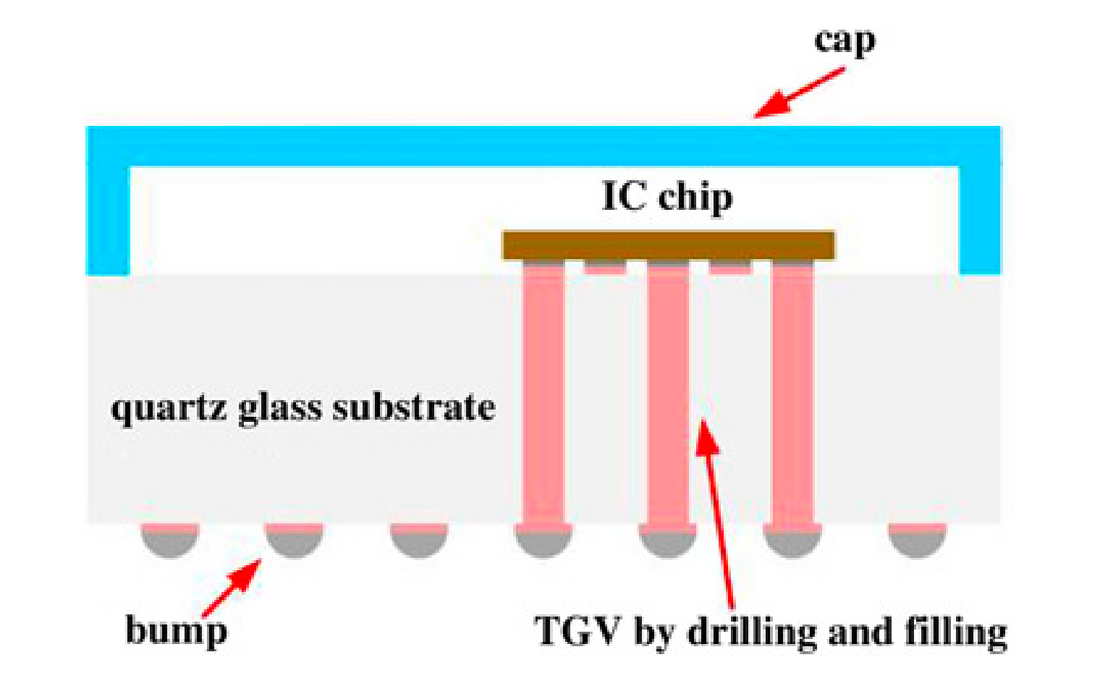

The article focuses on the advantages of quartz glass as a substrate material for 3D-IC interconnections, particularly its superior electrical isolation, optical transparency, high strength, and smooth surface, making it ideal for applications like MEMS, optical devices, and biomedical chips. Traditionally, TGV fabrication involved methods such as ultrasonic drilling, powder blasting, laser ablation, and electrical discharge machining, but these methods faced challenges in achieving precise via diameter and pitch, wafer thickness control, and mass production feasibility.

The authors demonstrate a novel TGV fabrication process utilizing inductively coupled plasma-reactive ion etching (ICP-RIE). This technique offers improved control over via dimensions and allows for the creation of high-aspect-ratio structures. The research explores the relationship between various process parameters (C4F8 and He flow rates, chamber pressure, ICP and bias power, cooling temperature) and their impact on the etching characteristics such as DC bias and sidewall angle.

The study analyzes the effects of different hard masks, structure dimensions, and glass substrate thicknesses on the etching rate and perforation morphology. The findings suggest that KMPR negative photoresist, compared to a Ni-Co alloy mask, proves more suitable due to its superior adhesion, durability, and ease of processing. Through meticulous optimization of the ICP-RIE process, the authors successfully fabricated TGVs with varying via diameters (50-300 µm) and depths (150-300 µm) on thin quartz glass substrates, achieving a high etching rate of approximately 0.416 µm/min.

The article concludes by emphasizing the successful development of a TGV formation technology using ICP-RIE, offering a promising approach for manufacturing high-quality, thin quartz glass interposers suitable for various 3D-IC packaging applications.

Origin: https://ietresearch.onlinelibrary.wiley.com/doi/epdf/10.1049/mnl.2016.0242