Micro-Hole Drilling on Glass Substrates—A Review

Citation

Hof, L. A., & Ziki, J. A. (2017). Micro-hole drilling on glass substrates—A review. Micromachines, 8(2), 53. https://doi.org/10.3390/mi8020053

Keywords

- micro-drilling techniques

- glass

- micro-devices

- micro-fluidics

- MEMS

Brief

This article is a review of established and emerging technologies for micro-hole drilling in glass.

Summary

This article from the journal Micromachines reviews different methods for drilling micro-holes in glass. Glass is a useful material for micro-devices because it is transparent to radio frequencies and has favorable optical, mechanical, and chemical properties. However, glass is also brittle and difficult to machine, making the drilling of smooth, high-aspect-ratio through-glass vias (TGVs) a challenge.

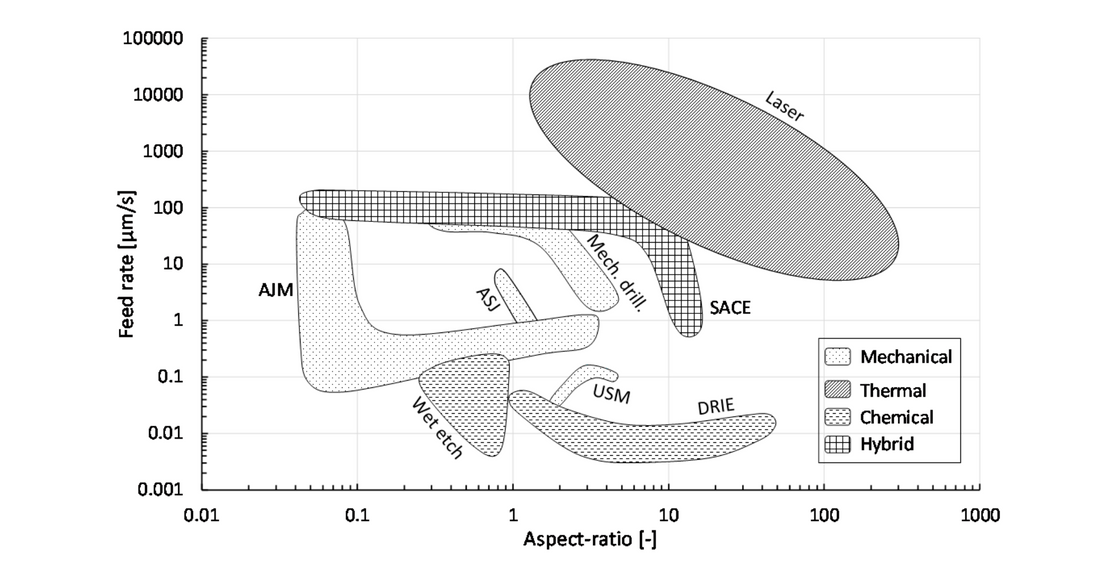

This review article summarizes and compares established and emerging technologies for drilling micro-holes in glass, grouping them into four categories:

- Mechanical Methods: These methods are generally affordable but can result in rough surfaces. They include:

- Mechanical Drilling: Involves a rotating tool that removes material, often using a pecking motion to clear debris. Mechanical drilling is cost-effective and good for rapid prototyping, but it can cause cracks.

- Powder Blasting: Employs a high-velocity stream of abrasive particles to remove material. Powder blasting is fast and doesn't create burrs, micro-cracks, or a heat-affected zone (HAZ). However, it results in rough surfaces.

- Ultrasonic Drilling: Uses a vibrating tool with an abrasive slurry to erode material. It can create small holes with high aspect ratios and straight walls, but it is slow, has high tool wear, and may cause chipping and cracks.

- Thermal Methods: These techniques can achieve high aspect ratios at fast speeds, but they can also result in low surface quality. Thermal methods include:

- Laser Machining: Uses a laser to ablate material. Laser machining is flexible and high-throughput, but it can create a HAZ and recast debris, making bonding difficult. Different types of lasers and techniques, such as CO2, excimer, liquid-assisted, PDMS-masked, and ultra-short pulsed lasers, offer various advantages and drawbacks.

- Chemical Methods: These methods use etchants to dissolve glass. While they can achieve good surface quality, they are slow and may require multiple steps and specialized equipment. Examples include:

- Wet Etching: Involves immersing the workpiece in a chemical etchant, usually hydrofluoric acid (HF). This isotropic process creates rounded sidewalls and can produce small features with smooth surfaces, but it has a low aspect ratio and risks pinholes and notching defects.

- Deep Reactive Ion Etching (DRIE): Uses plasma to create ions that chemically and physically etch the glass. While capable of high aspect ratios and smooth surfaces, DRIE has a slow etch rate and requires specific masks.

- Hybrid Methods: These methods combine two or more techniques to improve performance or overcome limitations. This category includes:

- Assisted Hybrid Micromachining: Involves using another form of energy to modify or enhance the primary machining process. Techniques in this category include vibration-assisted micromachining, laser-assisted micro-cutting, laser-induced plasma micromachining (LIPMM), water-assisted micromachining, chemical-assisted micromachining, chemical-assisted ultrasonic machining (CUSM), electrorheological (ER) fluid-assisted ultrasonic machining, EDM with an assisted electrode, and hot embossing.

- Combined Hybrid Micromachining: Involves the simultaneous action of multiple machining mechanisms. An example of this is spark-assisted chemical engraving (SACE), which uses electrical discharges in an alkaline solution to remove material. SACE can produce high aspect ratios with relatively smooth surfaces but can suffer from slow machining speed and limited flushing of debris.

The article concludes that the choice of micro-hole drilling technology depends on the specific requirements of the application, with trade-offs necessary between aspect ratio, surface quality, speed, and cost. Hybrid methods, in particular, offer a promising avenue for achieving desired outcomes by combining the strengths of different techniques.