SZPHOTON

Glass Core Substrate

Glass Core Substrate

total price (Based on quantity below)

The product listed below is made from our stocked materials and is for evaluation purposes only. For mass production, customization will be required.

Couldn't load pickup availability

Glass core substrates are a revolutionary new technology in the world of chip packaging. They represent a significant leap from traditional organic substrates, promising to usher in an era of even more powerful and complex integrated circuits (ICs).

Made with a core of glass instead of organic materials, these substrates offer several key advantages: superior stability, better heat dissipation, and improved electrical performance. This translates to the potential for cramming more transistors onto a single chip, leading to faster processing speeds and more powerful devices.

Standard Specifications

-

Material

Borosilicate Glass (Standard)

- Coefficient Thermal Expansion (CTE) = 3 - 9

- Density = 4.1 - 6.3g/cm3

- Leadfree: No

-

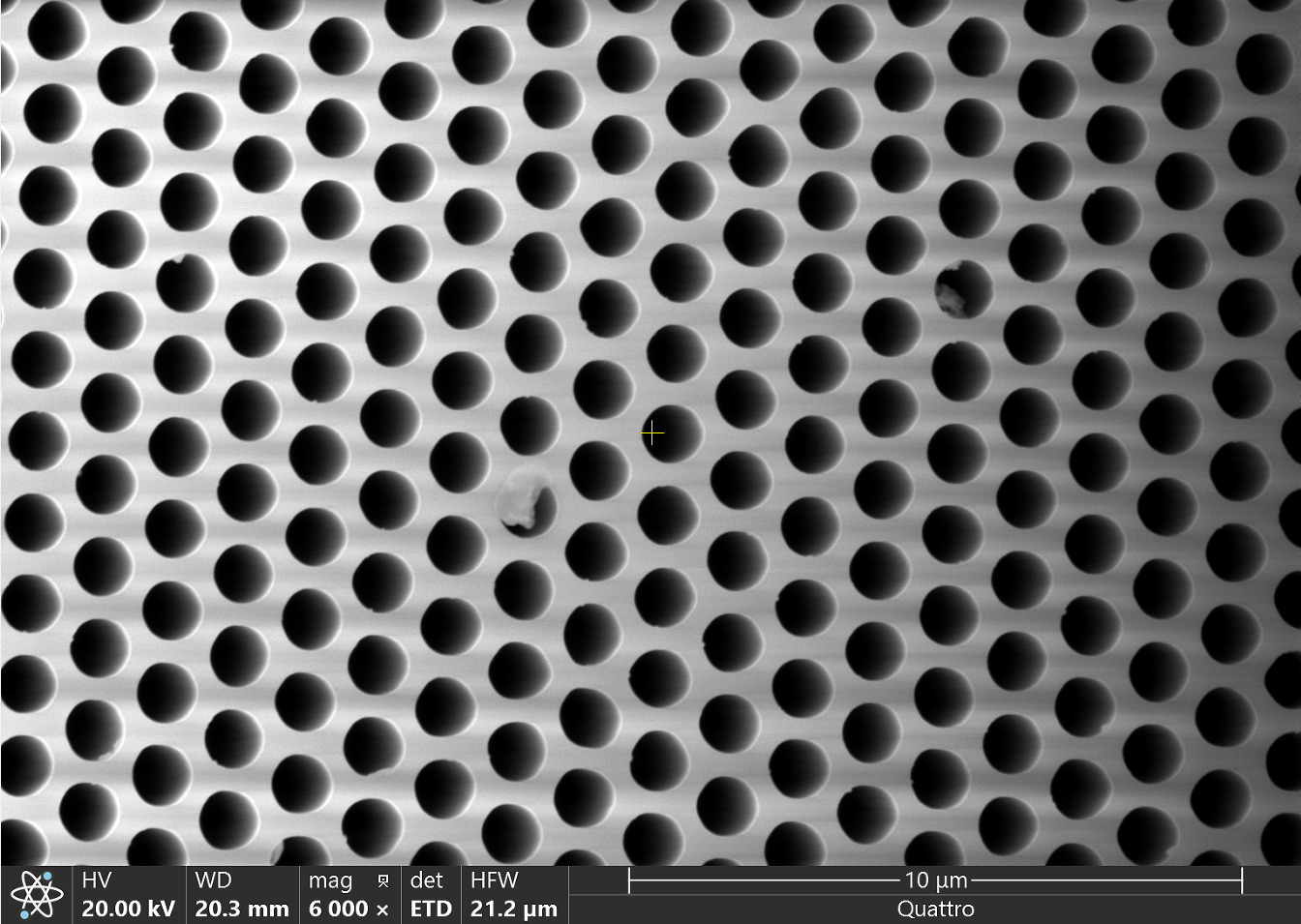

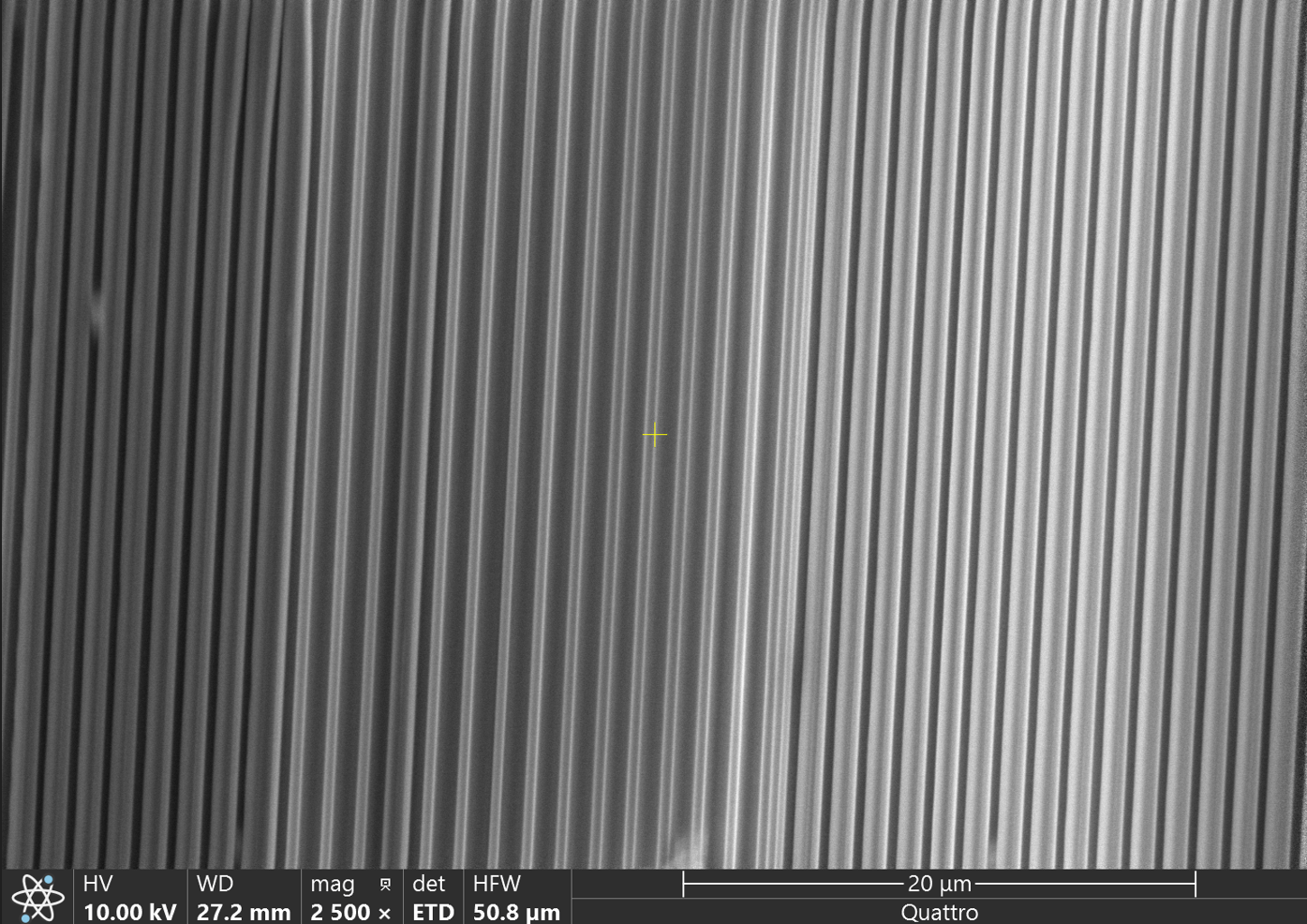

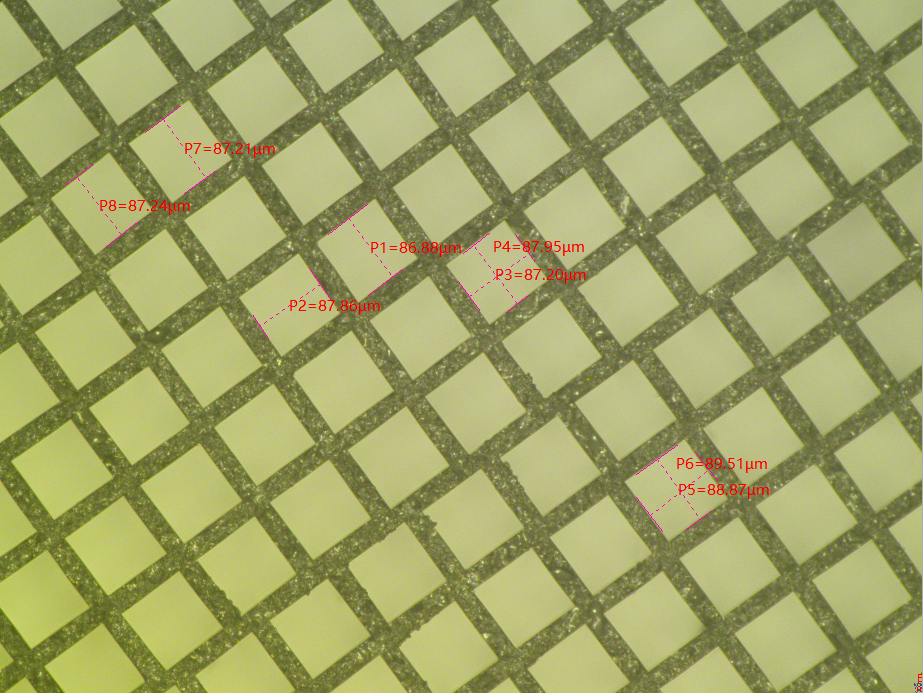

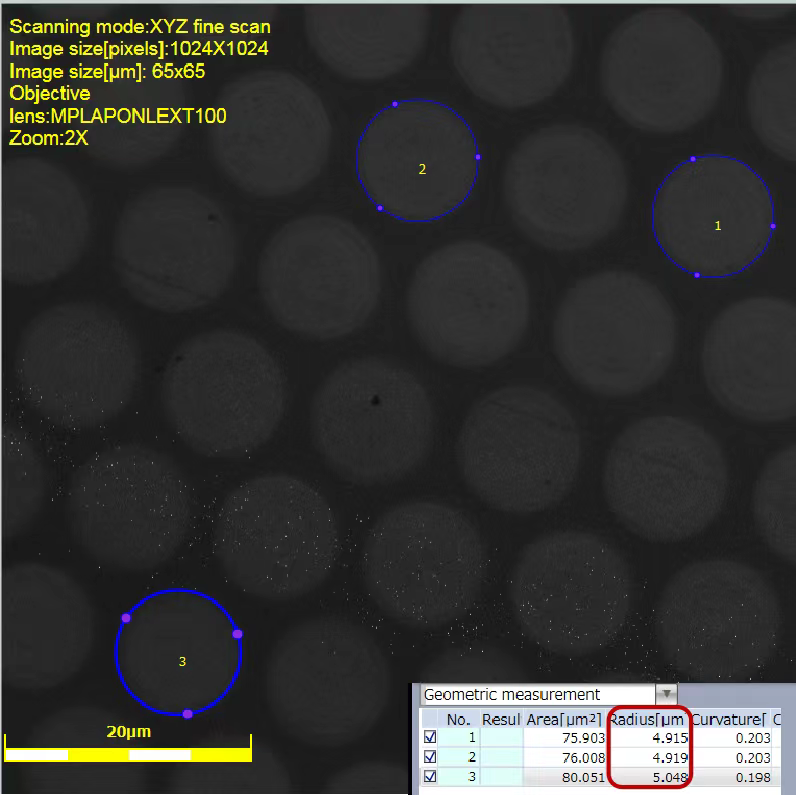

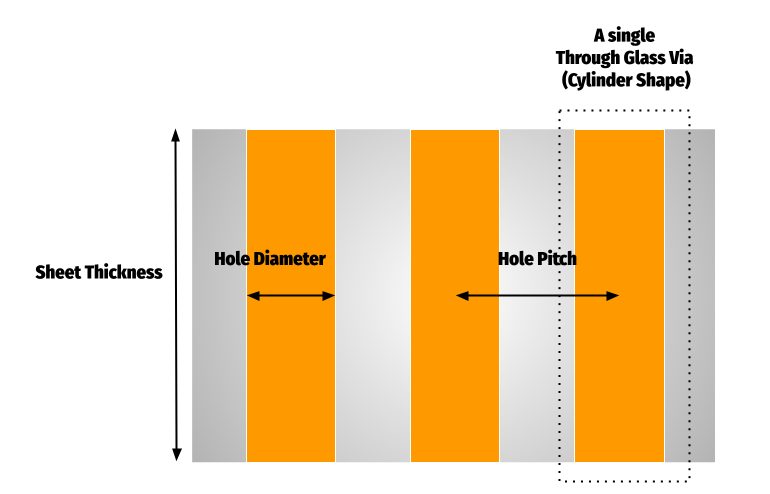

Hole Diameter / Pitch

Hole Diameter Available

- 1.5um (minumum)

- 100um (high range)

Hole Pitch Available

- 2 x Hole Diameter (standard)

- 1.25 x Hole Diameter (low range)

-

Sheet Dimension / Thickness

Sheet Thickness

- 0.3mm (standard)

- 0.2mm (low range)

Sheet Dimension Available

- 25 x 25mm (Cost -)

- 100x100mm (Cost ++)

- 150x150mm (Cost+++)

Additional Details

-

Coating

Coating can be made on the wall surface of the via.

(Pink area in the graph)

-

Quality Control Items

Below are items you can ask for a check before shipment:

- Visual Inspection

- SEM

- Thickness Tolerance

- Total Thickness Variation

- Warp

FAQs

Can I get other specification for sampling?

Yes, but the cost will be higher in such case. A minumum cost of 5,000USD will be there.

Is there any chance to reduce the price?

Yes, but due to our processing technique. We can reduce the price when the dimension is small (<dia26mm).

Also, we are not very capable in advanced mechanical processing. Higher surface requirement may increase the price significantly as well.

Can you make the Via taper shape?

No, due to our raw material and processing method. We can't make the Via (TGV) in taper shape.

Do i need the Via coming with Angle?

No you don't need. A straight Via is better than Via coming with angle.

To investigate the impact of the via diameter d, three values (50 μm, 100 μm and 200 μm) were assigned while the other variables were kept constant at h = 500 μm and a = 90°. The results reveal that this variation in via diameter has no significant impact on the insertion loss of the via up to 10 GHz. Beyond this frequency, the insertion loss of the 200 μm via degrades severely (approx. 60% of power is transmitted @ 50 GHz). The transmission coefficients of the 50 μm and the 100 μm via remain above 85% over the whole bandwidth.

Advantage of Glass Core Substrate

Glass core substrates offer some key advantages over traditional silicon base substrates, particularly for high-performance applications:

Thermal stability: Glass can handle higher temperatures without warping or degrading, which is crucial for managing heat in powerful chips. This allows for tighter packing of transistors and better overall performance.

Signal integrity: Glass has a lower coefficient of thermal expansion (CTE) that more closely matches silicon itself. This reduces stress on electrical connections during temperature changes, leading to faster and more reliable signal transmission.

Smaller vias: The ability of glass to handle tighter tolerances allows for the creation of smaller vias (holes for electrical connections) which can improve packing density and signal speed.

Optical transparency: While not always relevant, some applications can benefit from the transparency of glass, allowing for integration of optical components or light-based sensors.

Contact us

Reference

View all-

High density vertical optical interconnects for...

Citation D. Weninger, S. Serna, A. Jain, L. Kimerling, and A. Agarwal, “High density vertical optical interconnects for passive assembly,” Opt. Express, vol. 31, no. 2, pp. 2816–2831, Jan. 2023. ...

High density vertical optical interconnects for...

Citation D. Weninger, S. Serna, A. Jain, L. Kimerling, and A. Agarwal, “High density vertical optical interconnects for passive assembly,” Opt. Express, vol. 31, no. 2, pp. 2816–2831, Jan. 2023. ...

-

Live single cell imaging assays in glass microw...

Citation Sandström, N., Brandt, L., Sandoz, P. A., Zambarda, C., Guldevall, K., Schulz-Ruhtenberg, M., Rösener, B., Krüger, R. A., & Önfelt, B. (2022). Live single cell imaging assays in glass...

Live single cell imaging assays in glass microw...

Citation Sandström, N., Brandt, L., Sandoz, P. A., Zambarda, C., Guldevall, K., Schulz-Ruhtenberg, M., Rösener, B., Krüger, R. A., & Önfelt, B. (2022). Live single cell imaging assays in glass...

-

Miniaturised wideband bandpass filter with good...

Citation Zhou, Y., et al.: Miniaturised wideband bandpass filter with good selectivity based on 3D heterogeneous integrated passive device technology. IET Microw. Antennas Propag. 18(4), 266–271 (2024). https://doi.org/10.1049/mia2.12447 Keywords 5G...

Miniaturised wideband bandpass filter with good...

Citation Zhou, Y., et al.: Miniaturised wideband bandpass filter with good selectivity based on 3D heterogeneous integrated passive device technology. IET Microw. Antennas Propag. 18(4), 266–271 (2024). https://doi.org/10.1049/mia2.12447 Keywords 5G...